- Thread starter

- #41

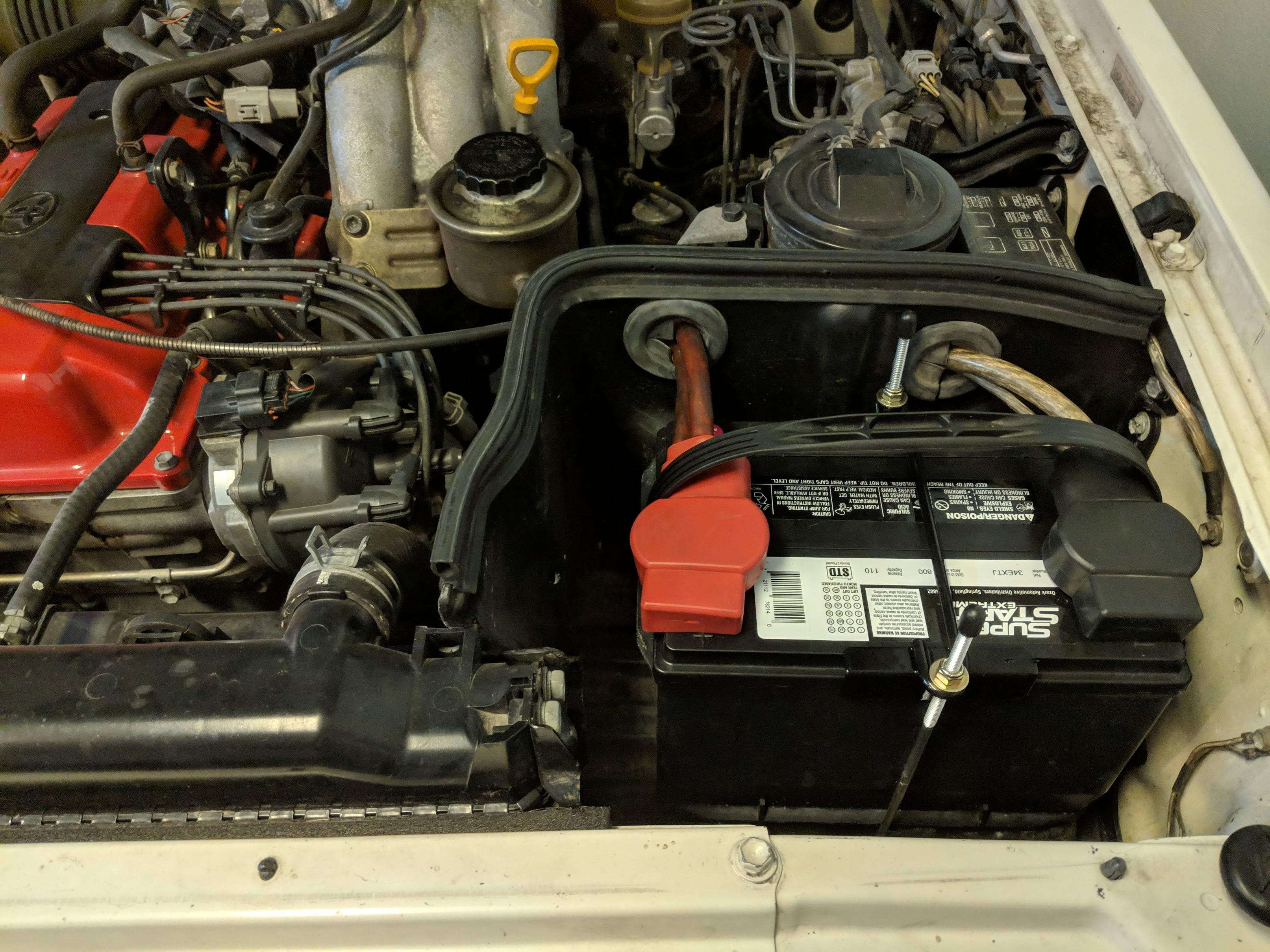

I edited my post, I thought for a minute your red jumper was a replacement fusible link for part of that setup.

Correct our red jumper relocates the links to a safer area. To add we only recommend using the red jumper power for the links only even though its rated for much more.