Well, like many on here, I’ve experienced the dead oil pressure gauge in the dash of my 80. While most would probably say, “replace the gauge and move on”, I am really cheap, and felt like taking the dash apart… Cliff notes: I ended up bending the gauge internals to get it to read again. Description on testing process and how to perform the crude adjustment follows:

To give you a little background. My gauge worked when I purchased my 80, and after I replaced the thermostat for some reason my oil pressure gauge didn’t register anything anymore, but it would occasionally bounce around. After some digging, I found I must’ve broken one of the wires to the sending unit while replacing the thermostat. By being lazy and not addressing it quickly, I believe the wire grounded out long enough to burn up the gauge, sort of. So, it eventually stopped bouncing and stayed dead all the time. Once I put a new terminal end on the wire and hooked it back up, it was too late. The gauge remained dead. So, I decided to figure out what I broke.

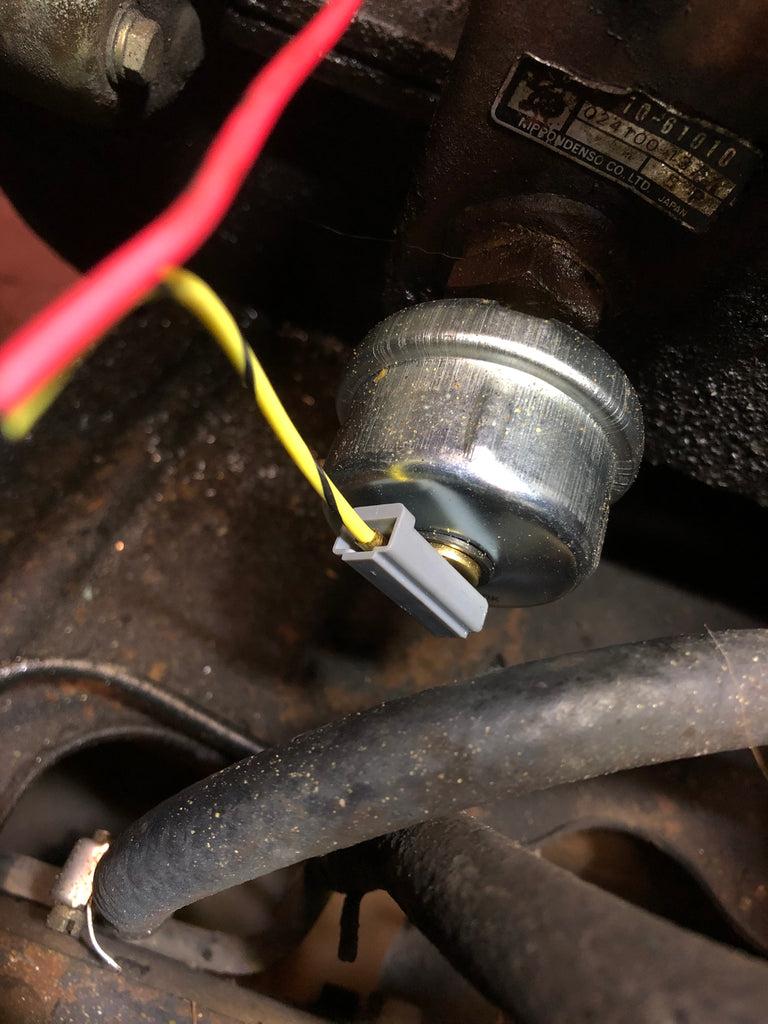

I started by performing the test in the FSM in order to determine if it was the gauge or sending unit. I started by testing the sender cause I didn’t have the 3.4W bulb required for the gauge test.

The sending unit passed the test (as expected); so, I had to find a 3.4w bulb at the auto parts store. I also bought a pigtail light socket for marker light that would fit the bulb while I was there. I then followed the FSM for testing the gauge.

While the FSM illustration is maybe a little confusing, I am assuming with the 3.4W bulb, the needle should sweep all the way to high based on the verbiage in the FSM. Well, while mine did sweep a little, which gave me hope, it fell short of making it to high (you can imagine the excitement as it began to move, and then total let down as it stopped short).

After doing some digging on here, I found some pics of people’s gauges with the engine off. While most people’s oil pressure needle rested right at the first mark when off, Mine well was well below.

So, the next step was to test the gauge resistance in the back of the combination meter aka cluster.

I really like to know how plastic dash pieces come apart before I dig in because if you think something is supposed to pop off and it’s not, you end up breaking plastic pieces, which is always heart wrenching… I found this great video on youtube that someone made on the cluster removal (if it was someone on here, THANKS it was very helpful!):

Once the dash was out, I again used the FSM to test it.

Based on the fact that I

1) had an in spec Ohms reading on the gauge

2) the gauge needle did move (though not much)

3) the resting position of the gauge was really low.

This led me to believe that when the wire grounded out while I was driving, it had buried my gauge so deep into the negatives and bent the internals of the gauge such that normal oil pressure wouldn't give it enough signal to lift off of zero. I decided to try to adjust the resting position of the gauge back to where it was supposed to be and see if that helped. To do this I had to remove the gauge from the cluster. This is done by:

1) Opening the cluster, which involves releasing the plastic tabs connecting the cover of the cluster. There are some on top bottom and both sides, so gradually and gently as to preserve old plastic.

2) Once the cluster cover is off. Remove the screws on the back of the cluster that are associated with the oil pressure gauge.

3) Once the screws are removed, the gauge can be gently pulled out.

With the gauge out, I was able to twist on the circled piece in the below pic until the gauge was resting at the first mark on the gauge.

Once I did that, I checked the ohms again, and I was actually a hair above spec post adjustment, but I decided to roll with it anyway.

Once reassembled, I test drove it, and it has been operating perfectly. In all honesty, I didn’t expect the gauge to operate in the same range as before, but as long as I had some repeatable operation, that’s all the accuracy I really see in the factory gauge anyway. So, I would say I’m super pumped at the outcome! I dug through the bowls of mud when I was trying to narrow down my problem and avoid buying another gauge, and at the time, I didn't see where anyone tried this. Hopefully, this thread allows others to give it a shot if you have similar test results.

To give you a little background. My gauge worked when I purchased my 80, and after I replaced the thermostat for some reason my oil pressure gauge didn’t register anything anymore, but it would occasionally bounce around. After some digging, I found I must’ve broken one of the wires to the sending unit while replacing the thermostat. By being lazy and not addressing it quickly, I believe the wire grounded out long enough to burn up the gauge, sort of. So, it eventually stopped bouncing and stayed dead all the time. Once I put a new terminal end on the wire and hooked it back up, it was too late. The gauge remained dead. So, I decided to figure out what I broke.

I started by performing the test in the FSM in order to determine if it was the gauge or sending unit. I started by testing the sender cause I didn’t have the 3.4W bulb required for the gauge test.

The sending unit passed the test (as expected); so, I had to find a 3.4w bulb at the auto parts store. I also bought a pigtail light socket for marker light that would fit the bulb while I was there. I then followed the FSM for testing the gauge.

While the FSM illustration is maybe a little confusing, I am assuming with the 3.4W bulb, the needle should sweep all the way to high based on the verbiage in the FSM. Well, while mine did sweep a little, which gave me hope, it fell short of making it to high (you can imagine the excitement as it began to move, and then total let down as it stopped short).

After doing some digging on here, I found some pics of people’s gauges with the engine off. While most people’s oil pressure needle rested right at the first mark when off, Mine well was well below.

So, the next step was to test the gauge resistance in the back of the combination meter aka cluster.

I really like to know how plastic dash pieces come apart before I dig in because if you think something is supposed to pop off and it’s not, you end up breaking plastic pieces, which is always heart wrenching… I found this great video on youtube that someone made on the cluster removal (if it was someone on here, THANKS it was very helpful!):

Once the dash was out, I again used the FSM to test it.

Based on the fact that I

1) had an in spec Ohms reading on the gauge

2) the gauge needle did move (though not much)

3) the resting position of the gauge was really low.

This led me to believe that when the wire grounded out while I was driving, it had buried my gauge so deep into the negatives and bent the internals of the gauge such that normal oil pressure wouldn't give it enough signal to lift off of zero. I decided to try to adjust the resting position of the gauge back to where it was supposed to be and see if that helped. To do this I had to remove the gauge from the cluster. This is done by:

1) Opening the cluster, which involves releasing the plastic tabs connecting the cover of the cluster. There are some on top bottom and both sides, so gradually and gently as to preserve old plastic.

2) Once the cluster cover is off. Remove the screws on the back of the cluster that are associated with the oil pressure gauge.

3) Once the screws are removed, the gauge can be gently pulled out.

With the gauge out, I was able to twist on the circled piece in the below pic until the gauge was resting at the first mark on the gauge.

Once I did that, I checked the ohms again, and I was actually a hair above spec post adjustment, but I decided to roll with it anyway.

Once reassembled, I test drove it, and it has been operating perfectly. In all honesty, I didn’t expect the gauge to operate in the same range as before, but as long as I had some repeatable operation, that’s all the accuracy I really see in the factory gauge anyway. So, I would say I’m super pumped at the outcome! I dug through the bowls of mud when I was trying to narrow down my problem and avoid buying another gauge, and at the time, I didn't see where anyone tried this. Hopefully, this thread allows others to give it a shot if you have similar test results.

Last edited: