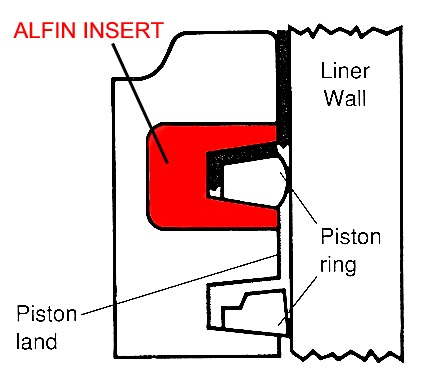

I was at the engine rebuilder today, and took this picture:

This piston came out of a running engine, that on top of this had one bent pushrod and a broken one!

I thought I would post this as an example on the weakness of the 12ht pistons, so people could see the actual problem and so it could be found when searching for the issue.

This piston came out of a running engine, that on top of this had one bent pushrod and a broken one!

I thought I would post this as an example on the weakness of the 12ht pistons, so people could see the actual problem and so it could be found when searching for the issue.