Rather than hijack Hulsty's build thread by rambling on in response to a question from Clint79 about a planned mod to my truck, I thought I'd start a build thread on this upcoming modification for my HZJ78 troopy...

I asked Marks4WD a few months ago, and they said their cruiser portals were still in development, but I think were getting closer to being ready.

I think they said somthing about them being more expensive, maybe a couple or a few thousand more than the Patrol portals, due to the 70 series birfields or knuckles or something like that not being strong enough to cope with the portal boxes, and needing to be replaced, or braced, or something. Or maybe it was due to the 70 series knuckles that push/weld into the axle tube, or something like that, needing to be replaced with a bolt on flange on the axle tube, which they might not need on the Patrol version. Can't remember the full story.

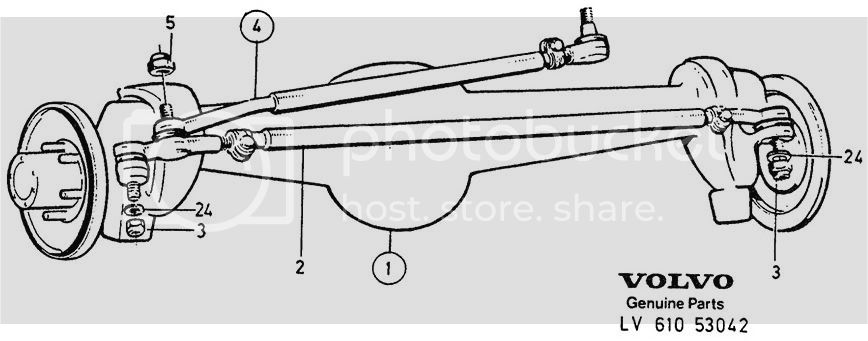

There are a few other portal options that I considered along with the upcoming Marks4WD Land Cruiser portal conversion, such as second hand Unimog portals, new PortalTek portals, and the second hand Volvo portals that I decided to go with for a few reasons.

I have already paid for a set of Volvo C303 portal axles from someone in the UK, along with half of the shipping cost, and they are apparently ready to be shipped.

They have been de-bracketted, had bearings checked, Land Rover kingpin bearing conversion and a hub seal conversion installed to use cheaper and easier to find parts, new rubber boots/covers for the birfields and new vacuum diff lock diaphrams fitted, have been painted, and hopefully will be dropped off at the shipping company very soon...

Once I get them in a couple of months, and have paid GST, import duty, and the rest I owe on the shipping, it will be probably six months to a year to get the money together to buy the extra bits, such as...

Have spoken to an engineer, he likes the idea and is seeing if we can get around the registration department maximum allowed 50mm increase in wheel track, as the Volvo axles have a wheel track that is 105mm wider than the standard HZJ78 axle for the front and 120mm wider for the rear, but he thinks it is a good idea as it will make it safer with the wider track to counteract the 4.5 inches that the portals lift the axles/diff centre/truck.

Standard HZJ78 Front Axle Wheel Track: 1435mm

Standard HZJ78 Rear Axle Wheel Track: 1420mm

Volvo Portal Axle Wheel Track: 1540mm

Increase in Front Wheel Track Over Standard: 105mm

Increase in Rear Wheel Track Over Standard: 120mm

If I can't get it engineered with the standard Volvo axle wheel track, I might consider having the Volvo axle wheel track shortened, if that is even possible.

Or it might be possible that a disc brake conversion will result in a narrower track, I have read that some ways of doing it does reduce the track, but others have told me it increases the track.

Required Reduction in Front Wheel Track for Registration: 55mm (27.5mm per side)

Required Reduction in Rear Wheel Track for Registration: 70mm (35mm per side)

The patrol kits around 18 g have marks adat made a cruiser kit yetSimonInAustralia said:Nice snow photos, I'm looking forward to it again very soon, just need another couple of snow falls.

There still are a few tracks that don't get closed, where you can drive until you get stuck in it, that's why I'm going to put portal axles under my troopy.

I asked Marks4WD a few months ago, and they said their cruiser portals were still in development, but I think were getting closer to being ready.

I think they said somthing about them being more expensive, maybe a couple or a few thousand more than the Patrol portals, due to the 70 series birfields or knuckles or something like that not being strong enough to cope with the portal boxes, and needing to be replaced, or braced, or something. Or maybe it was due to the 70 series knuckles that push/weld into the axle tube, or something like that, needing to be replaced with a bolt on flange on the axle tube, which they might not need on the Patrol version. Can't remember the full story.

There are a few other portal options that I considered along with the upcoming Marks4WD Land Cruiser portal conversion, such as second hand Unimog portals, new PortalTek portals, and the second hand Volvo portals that I decided to go with for a few reasons.

I have already paid for a set of Volvo C303 portal axles from someone in the UK, along with half of the shipping cost, and they are apparently ready to be shipped.

They have been de-bracketted, had bearings checked, Land Rover kingpin bearing conversion and a hub seal conversion installed to use cheaper and easier to find parts, new rubber boots/covers for the birfields and new vacuum diff lock diaphrams fitted, have been painted, and hopefully will be dropped off at the shipping company very soon...

Once I get them in a couple of months, and have paid GST, import duty, and the rest I owe on the shipping, it will be probably six months to a year to get the money together to buy the extra bits, such as...

- transmission handbrake ($1600AU for Hopper Stoppers kit, or something cheaper if I can find it and if it isn't too much of a drop in quality from the Hoppers Stoppers kit)

- somehow integrate the Land Rover Series 3 drum brakes, that the Volvo portal axles have as standard, with my Troopy brake system ($?AU), or maybe do a disc brake conversion to the axles ($?AU)

- standard 16x8 inch Volvo rims X5, with 8 stud pattern, ($600AU plus shipping, from a source within Australia), though not needed if getting disc brake conversion with 5 or 6 stud pattern before having axles fitted, and only if having the axle conversion engineered for registration purposes, to keep additional track width over standard to a minimum

- custom 16x8 inch rims X5, with 5 or 6 stud pattern and full 8 inch backspacing/full positive offset as per standard Volvo rims, (maybe $400AU each), only needed if getting a disc brake conversion done with 5 or 6 stud pattern before having axles fitted, otherwise use standard Volvo rims as listed above, and only if having the axle conversion engineered for registration purposes, to keep additional track width over standard to a minimum

- custom 16x10 inch rims X5, or X6, with 8 or 5/6 stud pattern depending on whether disc brake conversion, with 5 or 6 stud pattern, is done before having axles fitted, with maybe 7 inch backspace instead of the standard Volvo rim 8 inch backspace, depending on clearance between inside of tyre and steering/suspension after axles are fitted ($450AU each)

- if getting it engineered for registration purposes, a set of 275 or 285 R16 tyres X5 to comply with maximum 50% increase in tyre width over standard 7.50/R16 tyres ($?AU each)

- a set of 37 or 38 inch x 12.5 to 15.5 inch tyres X5, or X6 ($?AU each)

- a box to modify the speedometer calibration ($?AU), to suit the new diff final ratio and other gearing changes, and switchable to work with both the 275/285 registration tyres as well as the 37/38 inch offroad tyres.

- mods to guards/flares/wheel tubs, as/if required, so that the 37/38 inch tyres don't rub ($?AU)

- something to activate the standard Volvo front/rear vacuum lockers, either tapping into existing vacuum system, installing new vacuum pump/tank/solenoids/system, or changing standard Volvo vacuum locker operation over to being air or cable activated ($?AU)

- maybe a Marks4WD ($1825AU) or Terrain Tamer ($?AU) transfer case overdrive gearset, the Marks4WD version giving .92:1 (8%) high range overdrive and 2.81:1 (44%) low range reduction, and/or gearbox 5th gear swap ($?AU), to give increased overdrive to help deal with the Volvo 5.99:1 diff final ratio at highway speeds

- possibly look at having any parts of the front drivetrain that can be balanced, balanced ($?AU), to help deal with the speed that the front of the drivetrain will be spinning at highway speeds with the 5.99:1 diff final ratio, due to no longer having locking hubs after the axle conversion

- custom front and rear driveshafts ($?AU), balanced at least for the front due to no longer having locking hubs after the axle conversion, to help deal with the speed that the drivetrain will be spinning at highway speeds with the 5.99:1 diff final ratio

- RHD tie rod and steering link (?UKP), custom made for the Volvo portal axles in the UK, or something custom made locally ($?AU), or a set of original Volvo RHD tie rod and steering link sourced from Malaysia ($?AU)

- and then find someone who is a full time fabricator, with lots of diff swap/conversion experience, to fit them to my truck, hopefully doing a good/great job of it ($?AU), new coil hat/panhard rod/radius arm mounts on the front axles, new leaf spring perch/u-bolts/anti-wrap bar for the rear.

Have spoken to an engineer, he likes the idea and is seeing if we can get around the registration department maximum allowed 50mm increase in wheel track, as the Volvo axles have a wheel track that is 105mm wider than the standard HZJ78 axle for the front and 120mm wider for the rear, but he thinks it is a good idea as it will make it safer with the wider track to counteract the 4.5 inches that the portals lift the axles/diff centre/truck.

Standard HZJ78 Front Axle Wheel Track: 1435mm

Standard HZJ78 Rear Axle Wheel Track: 1420mm

Volvo Portal Axle Wheel Track: 1540mm

Increase in Front Wheel Track Over Standard: 105mm

Increase in Rear Wheel Track Over Standard: 120mm

If I can't get it engineered with the standard Volvo axle wheel track, I might consider having the Volvo axle wheel track shortened, if that is even possible.

Or it might be possible that a disc brake conversion will result in a narrower track, I have read that some ways of doing it does reduce the track, but others have told me it increases the track.

Required Reduction in Front Wheel Track for Registration: 55mm (27.5mm per side)

Required Reduction in Rear Wheel Track for Registration: 70mm (35mm per side)

Last edited: