Disclaimer

Be careful when doing your own car work and always, always, use jackstands of the appropriate size and weight capacity when it involves laying under a vehicle that is raised.

Tools/products I used:

Jack and jackstands

Short and/or deepwell 19mm, 21mm and 22mm sockets (6 point are recommended if you have them)

Flex head 1/2" breaker bar + cheater extension bar if needed (I needed it)

3" and 6" 1/2"drive extensions

3/8" ratchet and metric sockets set

19mm and 22mm open ended box wrenches

Med c-clamp (at least 6" jaw opening)

Torque wrench (up to 150ft/lb variety)

1/2" impact wrench (not necessary, but nice)

Razor blade or box knife

6" angle head curved jaw slip joint pliers

12"-24" pry bar

Wire brushes (small and large)

Spray lube/penetrant

Lots and lots of rags

Gloves

Tools I wished I had, at the time:

19mm flex head reversible gear wrench (would have worked great for the vertical bolt in the center)

6 point 19mm socket

Parts:

Enery Suspension P/N 8.10101G

Custom Sleeve from wheelersoffroad.com (7/8" OD x 5/32" Wall x 1.27" Long)

Teflon grease

Home brew puller:

36mm socket or equivelant

M12 x 100mm bolt and nut or equivelant (just under 4" long) - M10 or 3/8" or 7/16" bolt would also work *(remember: bolts/nuts are measured by thread size, not by head size or what wrench fits on them.)

Misc. washers

First things first, you are going to want to lift the front end off the ground, place jackstands under the frame rails, and remove the front tires. (You will have to loosen the front lugnuts before lifting up the front end, if you don't have access to air and an impact wrench.)

Next remove the four bolts that hold the rear portion of the skidplate to the chassis and slid it out, should look like this...

Right now is a great time to look for oil leaks from the front diff and transmission, and look for torn cv boots, worn components, etc.

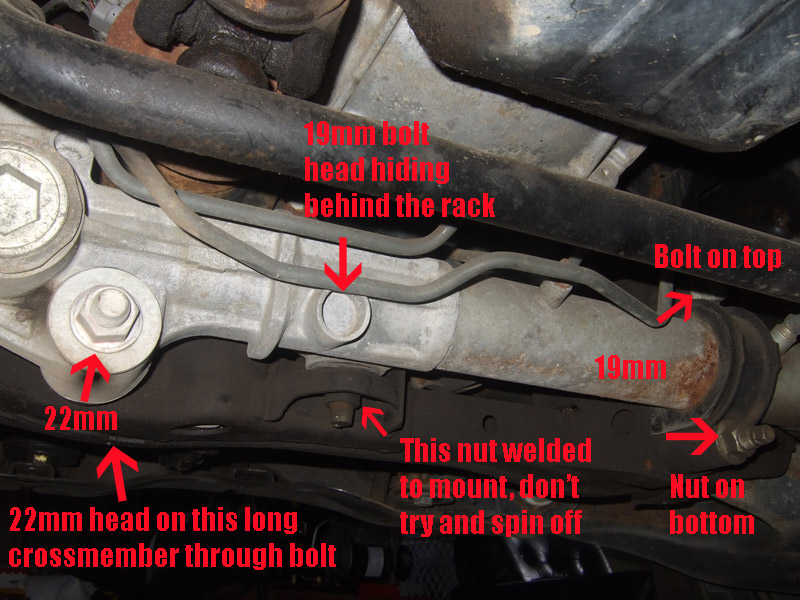

If you slid under the drivers or pass. side front door and look toward the front of the vehicle, this is what you should see. (Wrench sizes indicated, not bolt sizes)

Now it's time to remove fasteners, the left side and right side is very straight forward(though, I had to use a cheater bar for the bolts on the right side) The center bolt is the hardest to access.

Once I got it broke free, I used a 19MM box wrench to loosen it. I was just able to sneak it over the crossmember in front of the rack, not much room in there. (Here is where I wished I had a flex head 19mm gear wrench, would have saved at least 5-10 minutes)

This is what you should see with all bolts/nuts removed and pulled out about an inch.

Use a punch or a soft hammer to push the long bolt on the left out of it's bore and remove bracket on the right. Now you should be able to move the rack enough to have access to the center bushing.

The bushing on the right side is split and just slips off the rack.

I tackled the bushing on the left side next, if you peel up the bushing lip on the side you are looking at, and cut the lip of the bushing off it makes the next step easier.

After cutting off the lip of the bushing, take your slip joint pliers and grab hold of the big washer between the rack and the crossmember and twist it, it should come right out with a little persuasion......Get it out it will look like this. Make sure you clean up the bore, this pic was before I used a small wire brush to clean up inside there.

Next the center bushing.

The hardest bushing to get out can be made real easy with a homemade puller. (mad props to Merkaba55)

Gather the above mentioned home brew puller items...

Next gather them and meet me under the rack....100mm bolt and washer (larger than the inside diameter and smaller than the outside diameter) through the top....

Next socket to bolt and around the bushing....

Next, nut and washers as needed....bam! one bushing puller, I just hit mine with an impact but a wrench and socket (etc) works just fine also.

TA-DA!

Old stuff....

New stuff.......(the two shorter gold colored metal bushings that came with the kit where not used.....

Time to go back together, don't forget a liberal amount of Teflon grease, no one likes squeeky bushings/suspension....

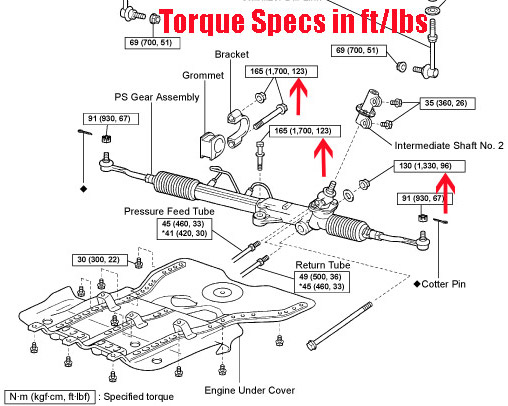

Torque specs for reinstalling......

Left side installed, lube up poly bushings and shove in both sides, they will be a tight fit......Make sure you put the new washer between the left rack bushing and the crossmember the new bushing doesn't have the washer built in.....

I found a med. c-clamp to be very helpful in pushing in the metal bushings after installing the poly bushings.

Started.....

and installed.......

The right side is pretty self-explanatory, grease bushing, slip over rack, install brace piece, tighten down evenly.

This is what you should see all back together, greased and torqued to spec.

Make sure to torque your lugnuts to 83 ft/lbs and.......

*Important*

Make sure you double check the torque again on all the bolts/nuts and your wheel lugnuts, after about 500 miles of use.

^^^^^^^^^

I've got to say of all the repairs/mods/upgrades to my 4Runner, this one has made the most noticeable difference in how it drove, the steering wheel is no longer shook from my hand on quick, short, washboard bumps and feels like a whole new front end was put under my truck.

Be careful when doing your own car work and always, always, use jackstands of the appropriate size and weight capacity when it involves laying under a vehicle that is raised.

Tools/products I used:

Jack and jackstands

Short and/or deepwell 19mm, 21mm and 22mm sockets (6 point are recommended if you have them)

Flex head 1/2" breaker bar + cheater extension bar if needed (I needed it)

3" and 6" 1/2"drive extensions

3/8" ratchet and metric sockets set

19mm and 22mm open ended box wrenches

Med c-clamp (at least 6" jaw opening)

Torque wrench (up to 150ft/lb variety)

1/2" impact wrench (not necessary, but nice)

Razor blade or box knife

6" angle head curved jaw slip joint pliers

12"-24" pry bar

Wire brushes (small and large)

Spray lube/penetrant

Lots and lots of rags

Gloves

Tools I wished I had, at the time:

19mm flex head reversible gear wrench (would have worked great for the vertical bolt in the center)

6 point 19mm socket

Parts:

Enery Suspension P/N 8.10101G

Custom Sleeve from wheelersoffroad.com (7/8" OD x 5/32" Wall x 1.27" Long)

Teflon grease

Home brew puller:

36mm socket or equivelant

M12 x 100mm bolt and nut or equivelant (just under 4" long) - M10 or 3/8" or 7/16" bolt would also work *(remember: bolts/nuts are measured by thread size, not by head size or what wrench fits on them.)

Misc. washers

First things first, you are going to want to lift the front end off the ground, place jackstands under the frame rails, and remove the front tires. (You will have to loosen the front lugnuts before lifting up the front end, if you don't have access to air and an impact wrench.)

Next remove the four bolts that hold the rear portion of the skidplate to the chassis and slid it out, should look like this...

Right now is a great time to look for oil leaks from the front diff and transmission, and look for torn cv boots, worn components, etc.

If you slid under the drivers or pass. side front door and look toward the front of the vehicle, this is what you should see. (Wrench sizes indicated, not bolt sizes)

Now it's time to remove fasteners, the left side and right side is very straight forward(though, I had to use a cheater bar for the bolts on the right side) The center bolt is the hardest to access.

Once I got it broke free, I used a 19MM box wrench to loosen it. I was just able to sneak it over the crossmember in front of the rack, not much room in there. (Here is where I wished I had a flex head 19mm gear wrench, would have saved at least 5-10 minutes)

This is what you should see with all bolts/nuts removed and pulled out about an inch.

Use a punch or a soft hammer to push the long bolt on the left out of it's bore and remove bracket on the right. Now you should be able to move the rack enough to have access to the center bushing.

The bushing on the right side is split and just slips off the rack.

I tackled the bushing on the left side next, if you peel up the bushing lip on the side you are looking at, and cut the lip of the bushing off it makes the next step easier.

After cutting off the lip of the bushing, take your slip joint pliers and grab hold of the big washer between the rack and the crossmember and twist it, it should come right out with a little persuasion......Get it out it will look like this. Make sure you clean up the bore, this pic was before I used a small wire brush to clean up inside there.

Next the center bushing.

The hardest bushing to get out can be made real easy with a homemade puller. (mad props to Merkaba55)

Gather the above mentioned home brew puller items...

Next gather them and meet me under the rack....100mm bolt and washer (larger than the inside diameter and smaller than the outside diameter) through the top....

Next socket to bolt and around the bushing....

Next, nut and washers as needed....bam! one bushing puller, I just hit mine with an impact but a wrench and socket (etc) works just fine also.

TA-DA!

Old stuff....

New stuff.......(the two shorter gold colored metal bushings that came with the kit where not used.....

Time to go back together, don't forget a liberal amount of Teflon grease, no one likes squeeky bushings/suspension....

Torque specs for reinstalling......

Left side installed, lube up poly bushings and shove in both sides, they will be a tight fit......Make sure you put the new washer between the left rack bushing and the crossmember the new bushing doesn't have the washer built in.....

I found a med. c-clamp to be very helpful in pushing in the metal bushings after installing the poly bushings.

Started.....

and installed.......

The right side is pretty self-explanatory, grease bushing, slip over rack, install brace piece, tighten down evenly.

This is what you should see all back together, greased and torqued to spec.

Make sure to torque your lugnuts to 83 ft/lbs and.......

*Important*

Make sure you double check the torque again on all the bolts/nuts and your wheel lugnuts, after about 500 miles of use.

^^^^^^^^^

I've got to say of all the repairs/mods/upgrades to my 4Runner, this one has made the most noticeable difference in how it drove, the steering wheel is no longer shook from my hand on quick, short, washboard bumps and feels like a whole new front end was put under my truck.

Last edited: