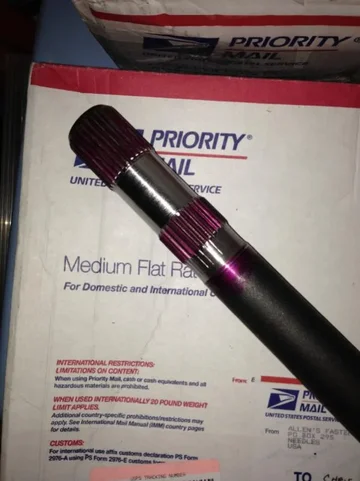

Background: Went north to Crusin the woods and managed to slightly twist the short side rear axle shaft. Just enough that the e-locker sticks when it disengages and has a real hard time re-engaging.

So my plan/question, has anybody or does it sound like a reasonable idea to turn part of the splines off the axleshaft. Just enough that the sliding collar sits on about half way on the splines unlocked. This way it will still be keyed or whatever you want to call it when it locks, but it the axle twists or even breaks the collar won't have any interference and you might be able to remove the broken part to get the third out?

I'm going to try it tonight since I have a messed up shaft. Unless its a really bad idea.

Matt

So my plan/question, has anybody or does it sound like a reasonable idea to turn part of the splines off the axleshaft. Just enough that the sliding collar sits on about half way on the splines unlocked. This way it will still be keyed or whatever you want to call it when it locks, but it the axle twists or even breaks the collar won't have any interference and you might be able to remove the broken part to get the third out?

I'm going to try it tonight since I have a messed up shaft. Unless its a really bad idea.

Matt