GTSSportCoupe

2LTE abuser

With the cold weather we had the past week, my injection pump (which had been seeping diesel), began seriously leaking. I had bought a seal kit last year when the seeping began, but had been putting off the job. The pump had stopped seeping through the summer when it got warm, which made it easier to procrastinate.

Anyhow, this job is certainly doable by the DIY'er. It is NOT easy though. Pulling the pump took 5 hours, cleaning and resealing it took about 5 hours, and replacing it took 5 hours. Might be faster on other vehicles depending on how hard it is to get at the pump. Cleanliness while working on the pump is of the utmost importance.

Here are some pictures I took of the process. Also, this is an electronic version of the rotary pump (2LTE). Would be roughly the same job for the mechanical rotary pumps though. I had to make a special thin 32mm wrench to get the spill control valve out. Also mounted it to a piece of wood to make it easier to work on.

Removing the pump is basically the same as doing a timing belt job. Then remove the pump pulley, injector hard lines, and mounting bolts.

Here is the dirty leaky pump after removal:

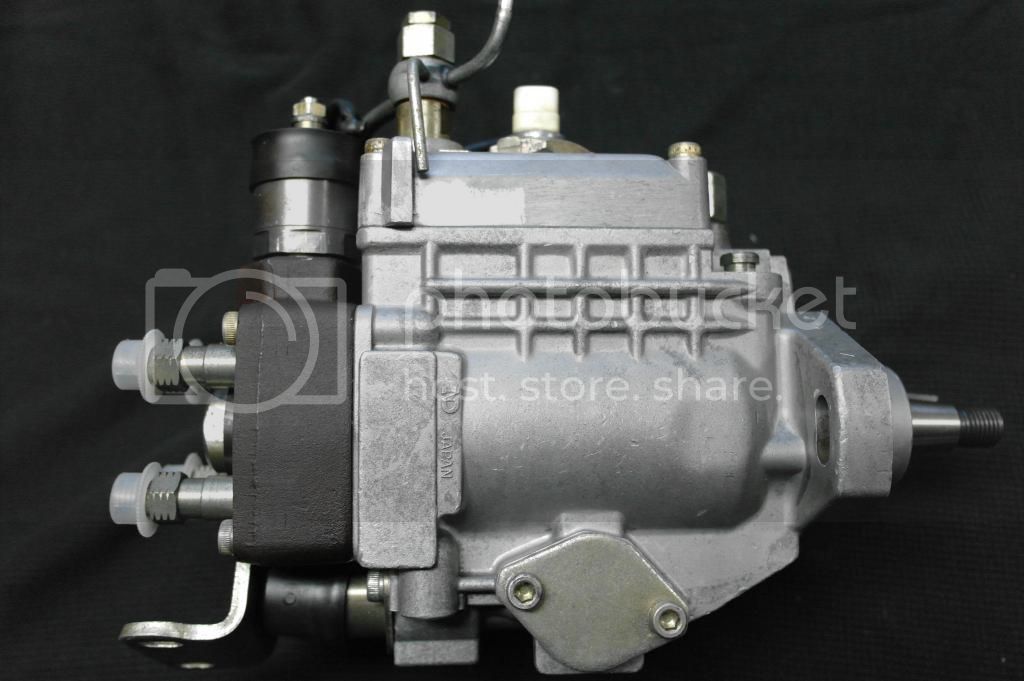

Pump after a good cleaning, blast with walnut shell and second cleaning:

Mounted it on a piece of wood (too lazy to make a metal mount).

Removed the Ne pick-up sensor and top cover to replace seals on both:

Removed lower side covers and replaced seals:

Removed timing control valve and replaced seal:

Removed spill control valve, replaced the seal, cleaned filter mesh:

Lifted pump head slightly (did not remove completely), cut out old seal, rolled new seal over the head:

Removed front shaft seal and replaced:

Anyhow, this job is certainly doable by the DIY'er. It is NOT easy though. Pulling the pump took 5 hours, cleaning and resealing it took about 5 hours, and replacing it took 5 hours. Might be faster on other vehicles depending on how hard it is to get at the pump. Cleanliness while working on the pump is of the utmost importance.

Here are some pictures I took of the process. Also, this is an electronic version of the rotary pump (2LTE). Would be roughly the same job for the mechanical rotary pumps though. I had to make a special thin 32mm wrench to get the spill control valve out. Also mounted it to a piece of wood to make it easier to work on.

Removing the pump is basically the same as doing a timing belt job. Then remove the pump pulley, injector hard lines, and mounting bolts.

Here is the dirty leaky pump after removal:

Pump after a good cleaning, blast with walnut shell and second cleaning:

Mounted it on a piece of wood (too lazy to make a metal mount).

Removed the Ne pick-up sensor and top cover to replace seals on both:

Removed lower side covers and replaced seals:

Removed timing control valve and replaced seal:

Removed spill control valve, replaced the seal, cleaned filter mesh:

Lifted pump head slightly (did not remove completely), cut out old seal, rolled new seal over the head:

Removed front shaft seal and replaced: