just ordered 2 - should have them in a few days

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rear window replacement gears (1 Viewer)

- Thread starter jynx

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?Who did you buy them from?just ordered 2 - should have them in a few days

WarDamnEagle

SILVER Star

Whatever happened to this?

Who's got the gears?

Dude, just click on the link that @fj55-100 posted and order them.Who did you buy them from?

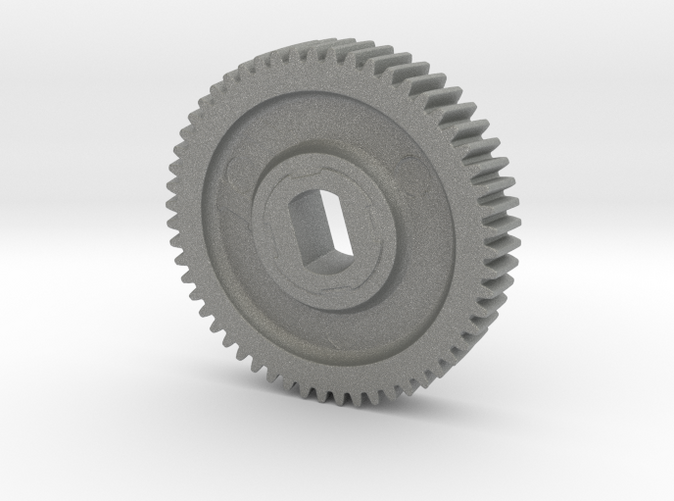

fj55 rear window gear by fj55_100 on Shapeways

Check out fj55 rear window gear by fj55_100 on Shapeways and discover more 3D printed products in Mechanical Parts.

Yep

WarDamnEagle

SILVER Star

So what flavor of Nylon 12 is everyone ordering? I was looking at the White Processed Versatile Plastic for $20 each.

Blastservices

SILVER Star

I just asked Evan and he sent me grey ones…So what flavor of Nylon 12 is everyone ordering? I was looking at the White Processed Versatile Plastic for $20 each.

Blastservices

SILVER Star

Here ya go! Pics for reference. Don’t forget to add some waterproof grease of some sort.

Looks good. Did you have your mechanicals replated?Here ya go! Pics for reference. Don’t forget to add some waterproof grease of some sort.

View attachment 2796062

View attachment 2796063

View attachment 2796064

View attachment 2796065

Blastservices

SILVER Star

Yes.Looks good. Did you have your mechanicals replated?

That looks great, I just ordered two. How much did replating cost? I would love to have this done just not sure around here where I could get this done.

There’s a shop in Utah that does yellow zinc plating.That looks great, I just ordered two. How much did replating cost? I would love to have this done just not sure around here where I could get this done.

FYI - I’m gonna use this shop in Utah.That looks great, I just ordered two. How much did replating cost? I would love to have this done just not sure around here where I could get this done.

Quality Plating Co., Inc. | Quality Plating

Blastservices

SILVER Star

So I did the prep work and lightly blasted with AE grade glass bead. At 25psi. You can’t just blast stuff and have it zinc’d or it will have a deep profile and look goofy.

You will want to call around your local area for an electroplating business and ask if they do yellow zinc. My cost and what someone else would pay will differ because I own a surface prep company. I do not do plating though. I just handed them to a customer of mine all prepped and said yellow zinc this please.

You will want to call around your local area for an electroplating business and ask if they do yellow zinc. My cost and what someone else would pay will differ because I own a surface prep company. I do not do plating though. I just handed them to a customer of mine all prepped and said yellow zinc this please.

Hey Blast,

When I bead blasted mine, there was a lot of residual material stuck in hard to get out of places. Window cranks were the worse. What was your method of flushing out the grit?

When I bead blasted mine, there was a lot of residual material stuck in hard to get out of places. Window cranks were the worse. What was your method of flushing out the grit?

Blastservices

SILVER Star

CFM is the key. Lots of volume of air. It’s not fair to compare because a home run or small business blast cabinet / compressor isn’t the same results as what is happening with my parts.Hey Blast,

When I bead blasted mine, there was a lot of residual material stuck in hard to get out of places. Window cranks were the worse. What was your method of flushing out the grit?

When you move a great deal of air and small amount of media (in this case spherical bead) it cleans properly as it should. If you are finding your media piling up on the surface you are cleaning it’s generally because your compressor isn’t pumping enough CFM. Which is very normal and not your fault it’s just most compressors cannot keep up with any type of blasting. But, most try anyways.

Dang, awesome, thanks!

Is there an ideal CFM that's obtainable with shop compressor to accomplish what your describing? Building shop this winter and putting together list of things I want to fill it.CFM is the key. Lots of volume of air. It’s not fair to compare because a home run or small business blast cabinet / compressor isn’t the same results as what is happening with my parts.

When you move a great deal of air and small amount of media (in this case spherical bead) it cleans properly as it should. If you are finding your media piling up on the surface you are cleaning it’s generally because your compressor isn’t pumping enough CFM. Which is very normal and not your fault it’s just most compressors cannot keep up with any type of blasting. But, most try anyways.

Blastservices

SILVER Star

This is a pocket reference one of the manufactures or real sandblast equipment gave me years ago. It’s pretty basic stuff. It’s not lieing either.

When it says nozzle size… think drill bit size… yep that’s right!

When it says nozzle size… think drill bit size… yep that’s right!

WarDamnEagle

SILVER Star

Interesting information. So maybe a better question is what's your business address so we can just mail our parts?This is a pocket reference one of the manufactures or real sandblast equipment gave me years ago. It’s pretty basic stuff. It’s not lieing either.

When it says nozzle size… think drill bit size… yep that’s right!

View attachment 2796331

fj55-100

SILVER Star

early gear is done ,.

www.shapeways.com

www.shapeways.com

FJ55-GEAR-early by fj55_100 on Shapeways

Check out FJ55-GEAR-early by fj55_100 on Shapeways and discover more 3D printed products in Mechanical Parts.

Good job! Thanks man, now everybody is covered.

Similar threads

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)