- Thread starter

- #61

What size intercooler did you end up using/calculating for your setup? (Compares to stocker.?)

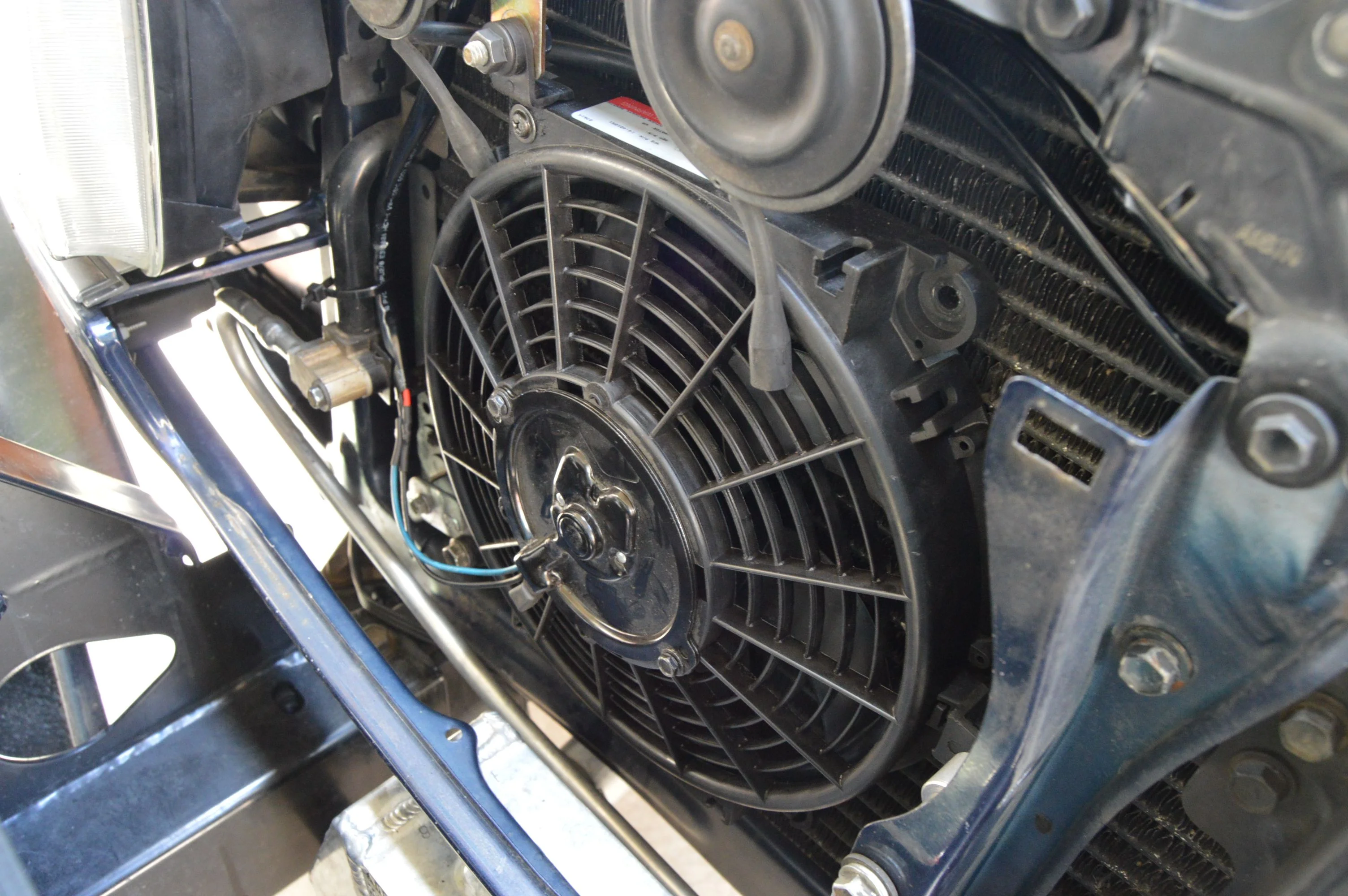

The core is 15 x 10 x 3.5, which is about double the volume of the stock intercooler, but with lower fin density. See earlier in this thread for photos without the bumper. It's basically the biggest I could fit in that area without sacrificing the ability to run a winch on the ARB.