PurpleFJ62 has a problem: the Cummins 6BTA Engine is out of the 99 Ram but has no way of mounting to the piddly little piece of s*** engine stand you buy at autozone crapo. This little thing is rated at 1250 lbs, and the Cummins weighs approx that (1170).

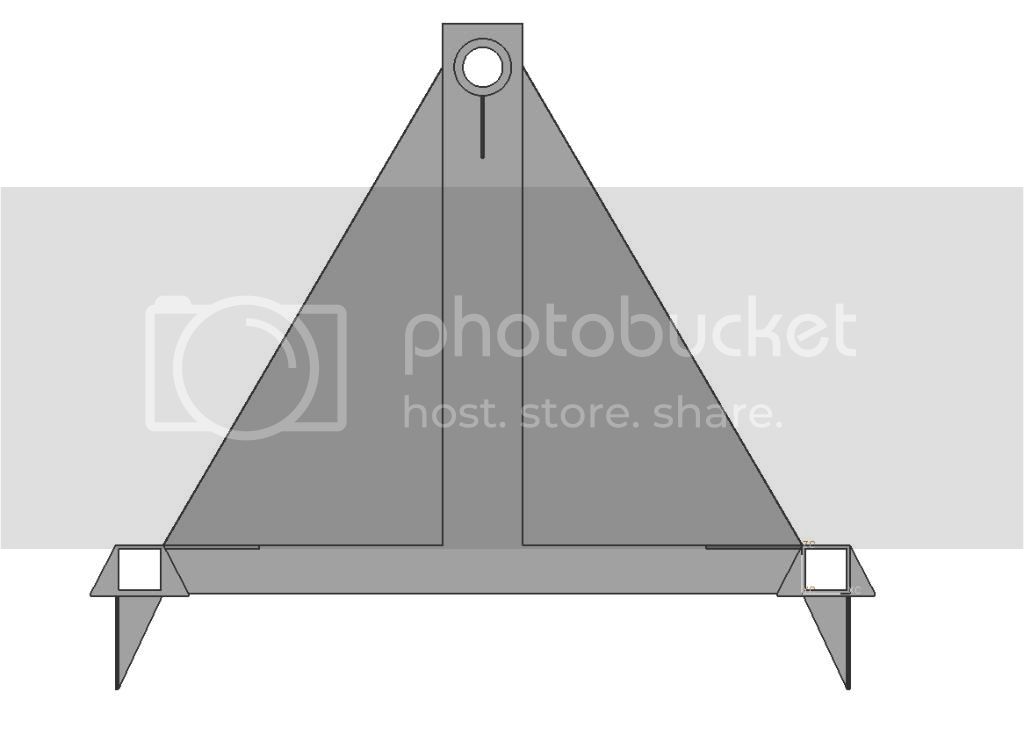

So, I design this using CAD software NX3 and FEA'd it to ensure is rigiidity and durability. According to the software. the base structure (not the head tube or the caster wheels) can support approx. 10000lbs before the structure yields.

Pictures:

CAD Model

Fabricating the Inner Tube:

Used a Rotary Table and a HUGE drill press (Radial Super Service Machine) at Detroit Diesel to make the radial holes for the locking pin:

So, I design this using CAD software NX3 and FEA'd it to ensure is rigiidity and durability. According to the software. the base structure (not the head tube or the caster wheels) can support approx. 10000lbs before the structure yields.

Pictures:

CAD Model

Fabricating the Inner Tube:

Used a Rotary Table and a HUGE drill press (Radial Super Service Machine) at Detroit Diesel to make the radial holes for the locking pin:

.

.