These types of projects are rarely "worth the cost". People do it for the challenge and therapy. It's better than playing golf and might be cheaper than going to the strip clubs. Cheap, as in you're not going go through a divorce

The answer to your second question is ALWAYS going to be a YES! Leave your 80 alone and enjoy it for camping and wheeling then get a more economical transportation for going to work and such. You'll be money ahead as well as time. Remember, these projects eat up a LOT of time, which can be spent making memories with your family on trips.

Just my .02 cent

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Builds Cummins R2.8 H151 Swap into 1993 FZJ80 (6 Viewers)

- Thread starter PurpleFJ62

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?The r2.8 has to be imported from eeuu it is expensive. Buy finding a toyota engine is difficult and expensive. I Will send some pictures later that i blow up the engine and i am re bulding 100% with oem parts ha jajaja but next week is ready and heading to the jungleCan you get the R2.8 in Ecuador?

The Toyota diesel bolts in and is a smooth six cylinder, I would go that route if you want a diesel.

As you can imagine either route costs a lot of money.

Share some pictures of the rigs from Ecuador!!

Any contact info for him?If anyone is in the market for offroad only tuning for the little R2.8, I suggest you find the delete king on facebook. He can help you out with your tuning solutions.

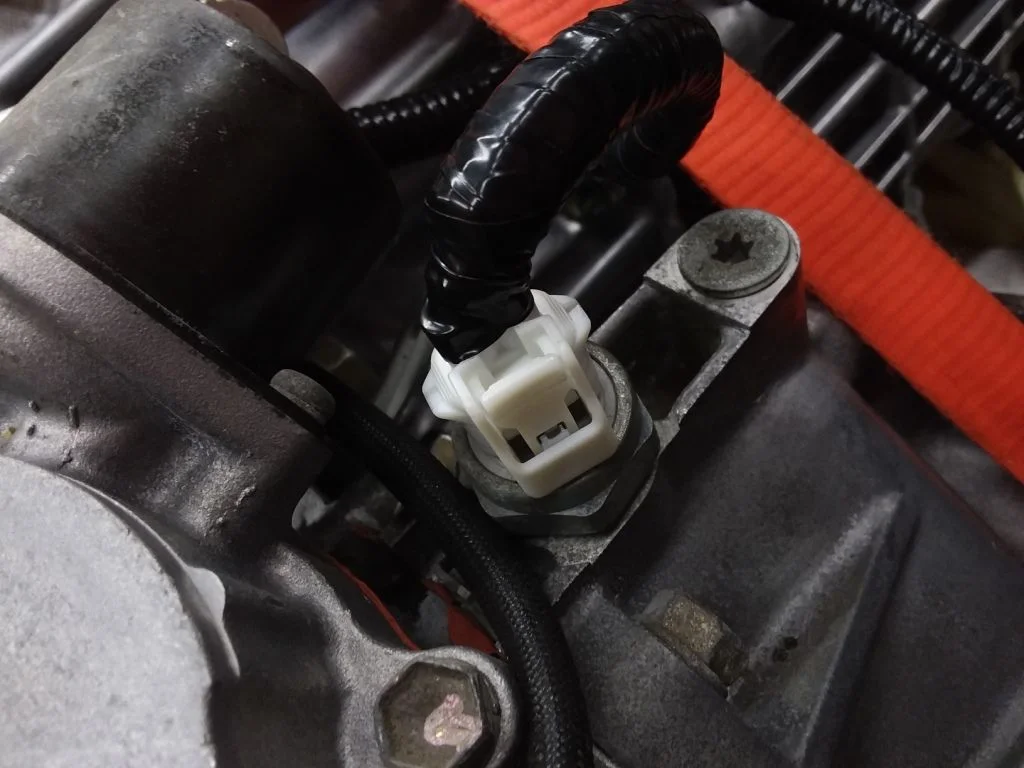

Amazing work. You're in Dallas, TX? Me too...about to start an R 2.8 swap into an FJ-55. Is it okay to contact you?Not much of an update for you guys, I did manage to get the heater hoses fixed up. I put new rubber and clamps on the heater core lines since it would be very hard to do when the engine is installed. Also that funny black pipe thing was leeking slowly on my 1FZ, got a new one cheap from toyota parts deal.

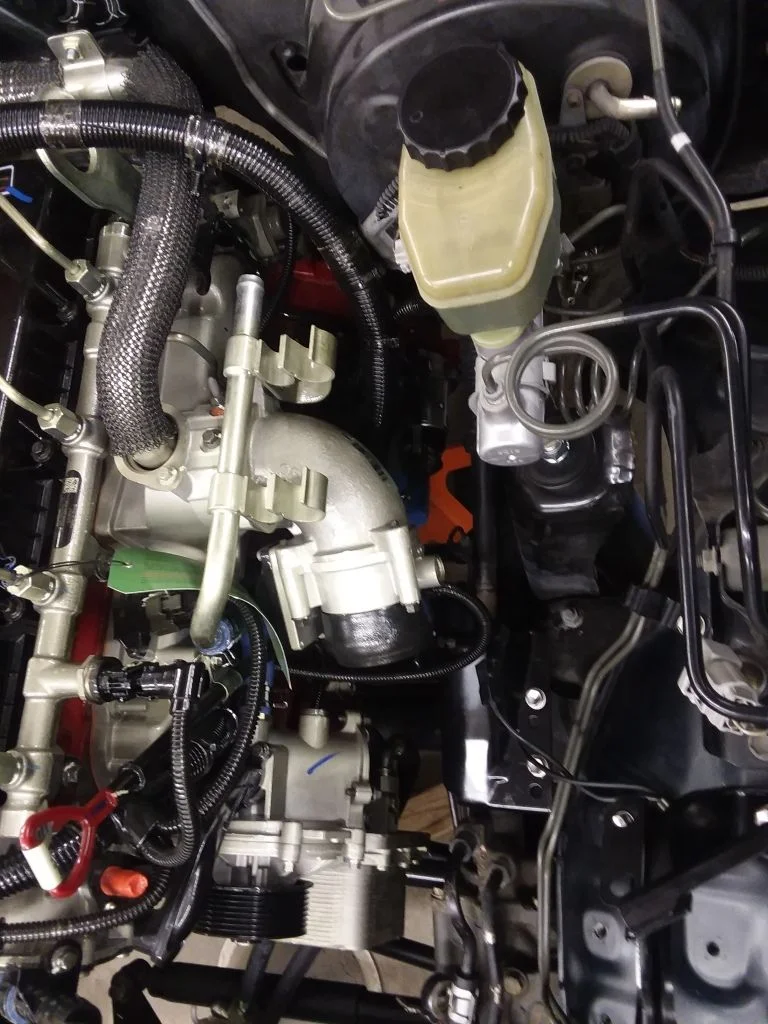

The R2.8 has a little different routing for its heater lines, I made this little stainless fitting because I could not find an T-fitting that had outlets in all three coordinate directions, but this will work very well with the R2.8 I think.

Be careful with these hoses, the curved ones dont seem to be available seperatly, they are part of the rear heater hose assembly. Maybe a master could chime in on this, I had to reuse the 90 degree hose.

I also began working on my trans/t-case harness. Toyota does splices and wraps them in blue tape, I dident feel like working hard yesterday so I put some solder on them.

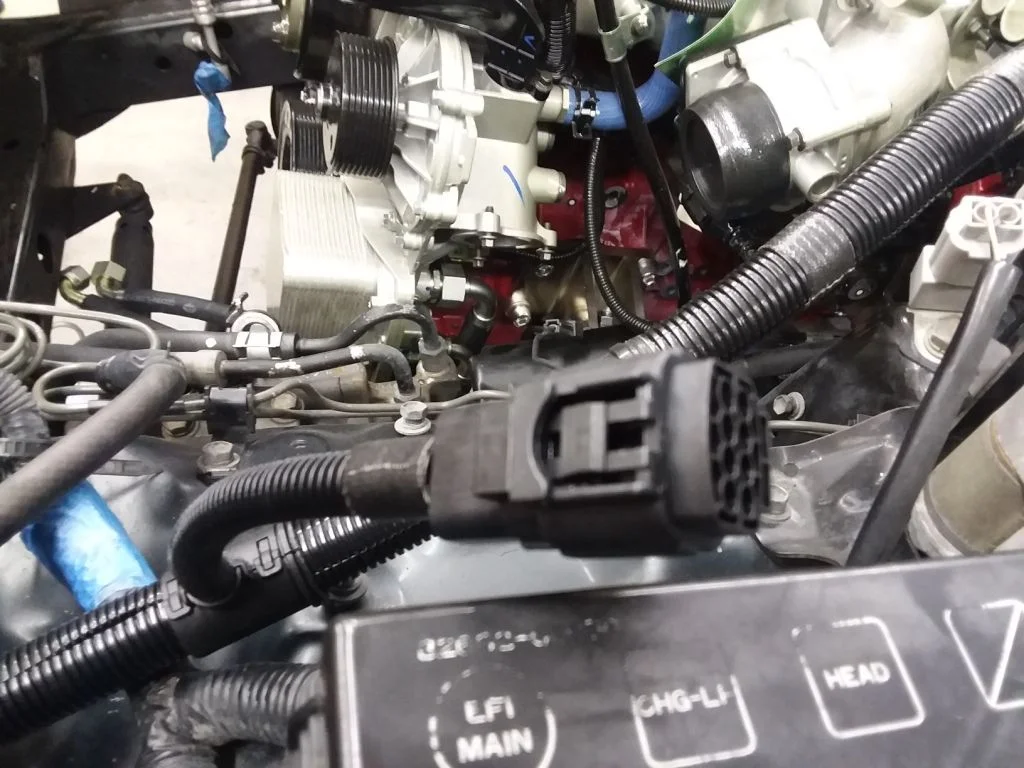

I broke a connector on the harness a few months ago so I need to fix that. I just learned that if you put 90980 in front of the number on the connector body you magically get the Toyota part number, how helpful!

Also got the throttle pedal installed, I hope the placement is good. I dont have seats installed at the moment so I could not sit in it and test. I ditched the cummins bracket, it does not work with an 80 series.

I had to drill the threads out of the pedal assembly so the bolts could be installed from the left instead of the right because I could not fit my hands in such tight space.

Finished product

Sorry if I missed it, but what function does the connector serve? Thanks!Thanks for getting my back there! I agree with you 100%. If you want MPG I would suggest a VW TDI if you live in a place where they are not illegal, if your in commiefornia then a prius.

As for the comments about towing and doing heavy work, i'm not sure what to say. For the day when you need to haul a cubic yard of limestone get a real truck.

Previously I mentioned repairing broken electrical connectors on your harness, i'm sure others will need to do this given the age of our rigs. I already mentioned how to derive the toyota part number. For doing the surgery you need a super thin screwdriver and perhaps magnifying glasses. Toyota has a manual that is excellent on this, it is RM06H0E for your reference you need to download it, its amazing.

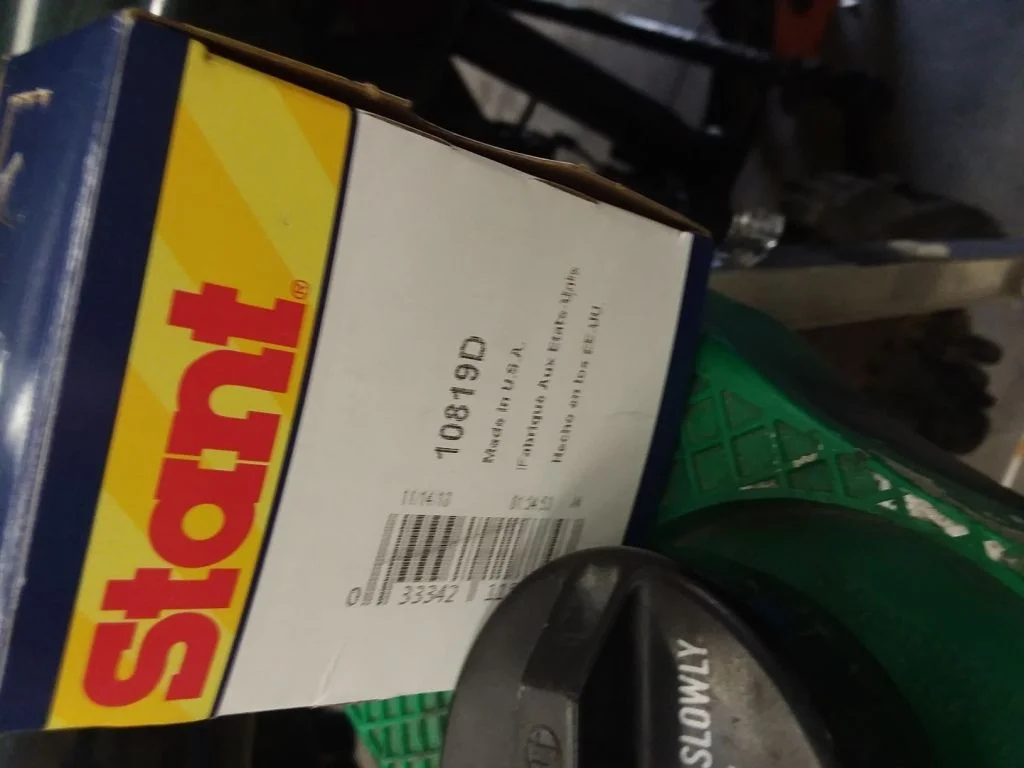

I followed the lead of others for the diesel cap. I think it was Rock40 that posted a pic of this Stant Cap he found, something like 5 bucks on rockauto. Easiest part of the swap thus far.

And the finished product

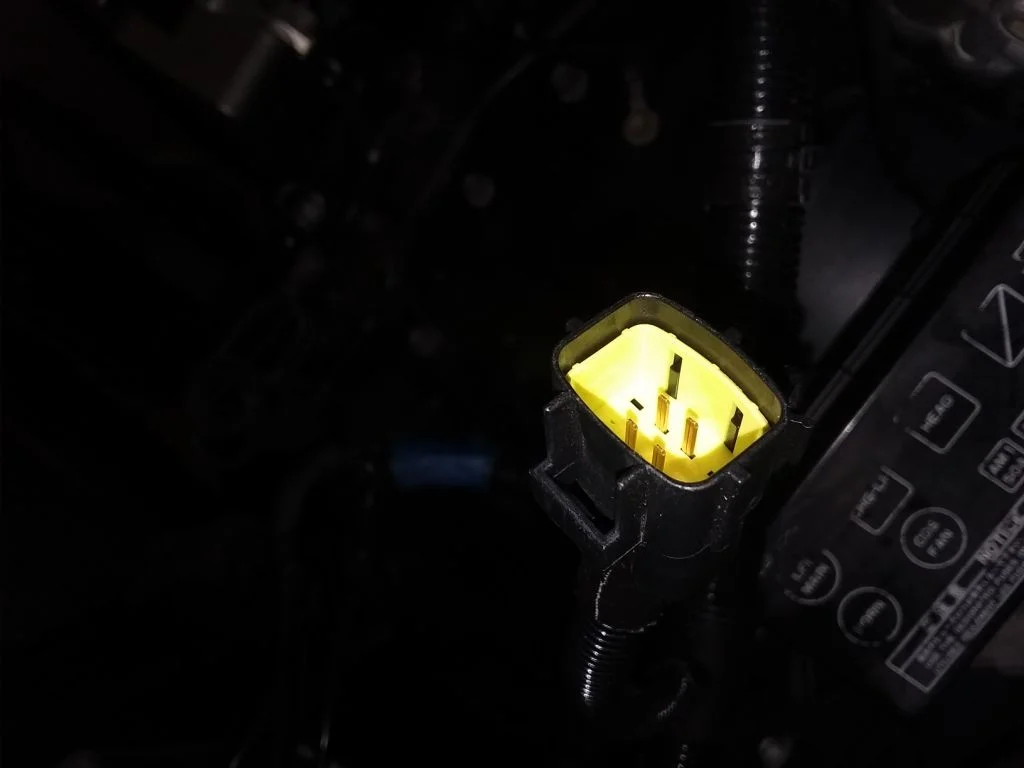

On other fora there has been some questions about this mystery plug on the R2.8 harness. Since Cummins is not smart enough to tell people what it is and their tech support is incapable of figuring out the answer it falls on my shoulders.

The plug in question is...

I have confirmed that this connector mates, but I have yet to install the pins and actually use it.

Amazon product ASIN B00N7821LI

I also have some crappy pictures of my trying to hold the fuel filter in my proposed location.

As you guys can see there is no room on the LHS of the engine bay...

Someone suggested locating the oil filter on the left chassis rail down by the shock tower, not going to happan. Like I said, its an asbolute monster and it does not even have fittings on it which will add a few inches since they are about the size of -10 or -12 AN.

You can use the T-cooler, but you still won't get 1000 mpg, haha. Sorry...couldn't resist. This is an amazing build!!This evening I was able to make a little progress on the mutant beast. After the recent polar vortex we had to endure here in Michigan I decided to add another battery since even my 3VZ almost did not start, and after all its a Land Cruiser, it should not have to fear cold weather.

I found a deal online for a FJ80 battery tray, it did not fit as good as the OEM FZJ80 one, the holes needed to be enlarged just a little bit. Here it is pictured with the battery from the LHS to test fitment. I dont happen to know off hand which way the battery is supposed to be installed, it seems that the clamping bar is kinda close to the battery terminals.

I decided to do this now because I am getting close to having to design a cooling package for the engine and turbo, so I want to make sure that it fits around the dual battery setup.

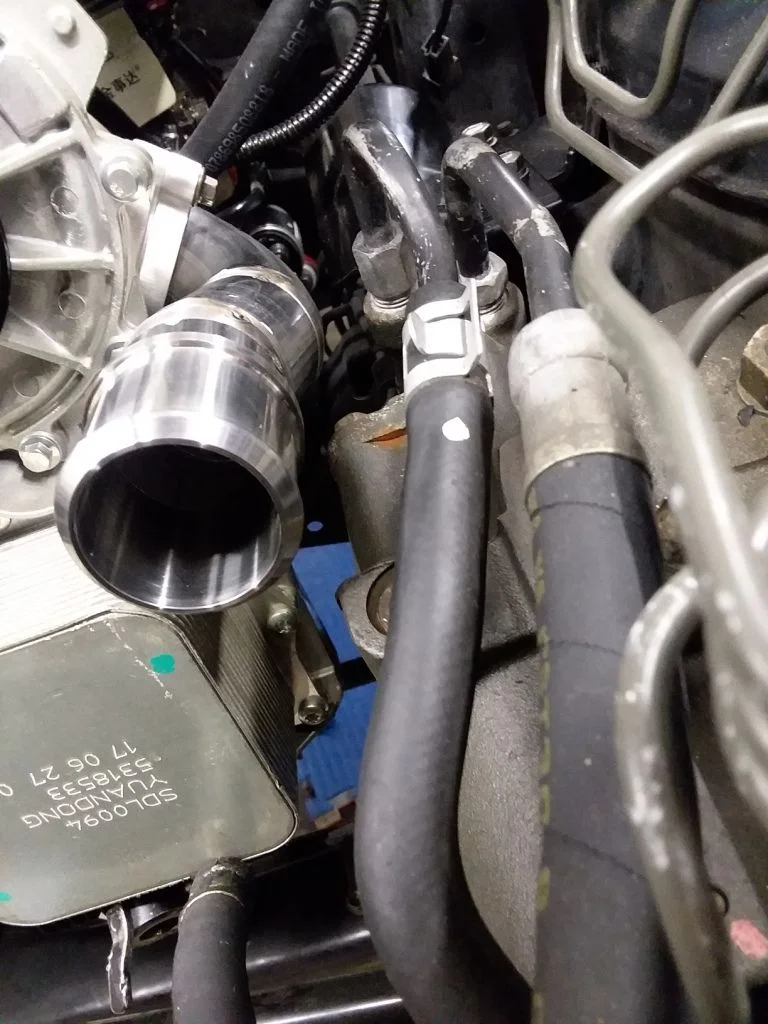

Another item from long ago was the coolant outlet, as I mentioned before the R2.8 coolant outlet will touch the steering box. Since I am not a fan of altering excellent toyota engineering, I decided to engineer some of my own crap. I previously posed some pictures of the machined stainless steel parts that I intended to use to work around this problem. I found these slick things called pie cuts, I got one from stainless brothers out of Austin Texas. This along with a 90 degree bend and some straight sections allowed me to make this rather odd looking thing.

I need to rig up something to back purge before finishing the welds, i'll try to bang that out this weekend.

For reference here are two shots of the R2.8 coolant outlet installed, as you can see its very very close to the steering box.

Here is my homemade one installed...

This fits much better, and as long as the motor mounts dont break we should have no contact between coolant outlet and steering box.

Looking ahead to the future I see lots of plumbing issues since the power steering pump will now be on the opposite side of the engine bay. I removed this mess of hard and soft power steering line to free up space for intercooler plumbing, I dont think it will be much use anyways.

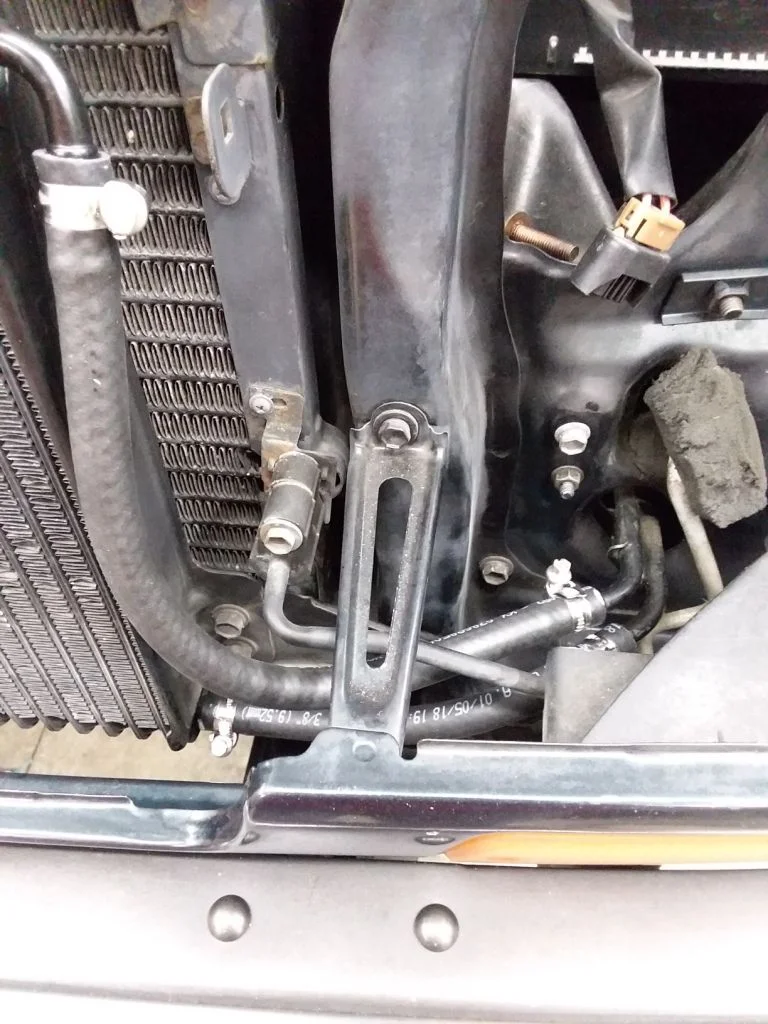

I know the OEM's use these cheesy things to help cool the power steering fluid, but I think we can do a little better. Since I ditched the A442 I just happen to have a kick ass trans cooler that already has factory brackets. I'm not sure if anyone has used an old trans cooler for this purpose but I dont see any reason what it would not work. I have had the privilege of installing some B and M trans coolers on other vehicles and from handling this unit I am left with the impression that the LC cooler is built a good bit better. Anyone care to challenge that claim?

I think I could plumb the power steering system using that neat little hard line thing that passes through the sheetmetal just below the LHS headlight, sorry but I dont have a picture handy at the moment. Im sure the 80 series guys know what i'm talking about.

==========================Edit=======================================================

Here is a picture of the core support pass thru, its the details like this that separate the land cruiser for just about everything else. What ever cooler is decided on this will allow for super clean plumbing.

When do you sleep??? What really cracks me up is when you ask for advice or input and we are like looking around, like "What??? From me???" This is a Master Class in innovation, creative engineering and mechanical ability, all presented in a down to earth, easy(ish) to follow dialog. Really digging on this!!Well finally decided on the power steering cooler, i'm going to use the factory A442 trans cooler. This thing is an absolute beast!!

I found a device to help control fluid temperature so the fluid will still be able to get up to the correct operating temperature.

Mr. T did a really nice job designing the mounts for this cooler, there is a reason these rigs last so long!

I used some high quality hose from McMaster Carr, its rated to 50psi. I think the return circuit on the power steering system is well below this value, can anyone comment? The hose is made specifically for petro based chemicals so hopefully that will not be a problem. Some stainless hose clamps top everything off.

For those intrested you can find the thermostat here

Earl's Performance 501ERL Earl's Performance Engine Oil Thermostat | Summit Racing

Free Shipping - Earl's Performance Engine Oil Thermostat with qualifying orders of $109. Shop Remote Oil Thermostats at Summit Racing.www.summitracing.com

I figure if it can work for engine oil then power steering fluid shall also be ok.

Yeah, I'm always amazed by people who hope for good mileage while driving a 40-50 year old assault vehicle that weighs 2.5 tons and has the aerodynamics of a wall.I went off my google search, and shortened it in layman's terms to keep it simple, I never think that hard on my cruiser or any vehicle, I know my Cummins should do 20+ MPG, but I enjoy it so much that I get 18-20 and if I was shooting for fuel economy, I would not be driving a 5400# brick

That was my first thought. Lots of new parts heating up, oil and grease from the build in places they aren't gonna stay, rings seating and so on....It is a brand new motor, and may take a bit to burn the stuff off from the build

Similar threads

Users who are viewing this thread

Total: 7 (members: 0, guests: 7)