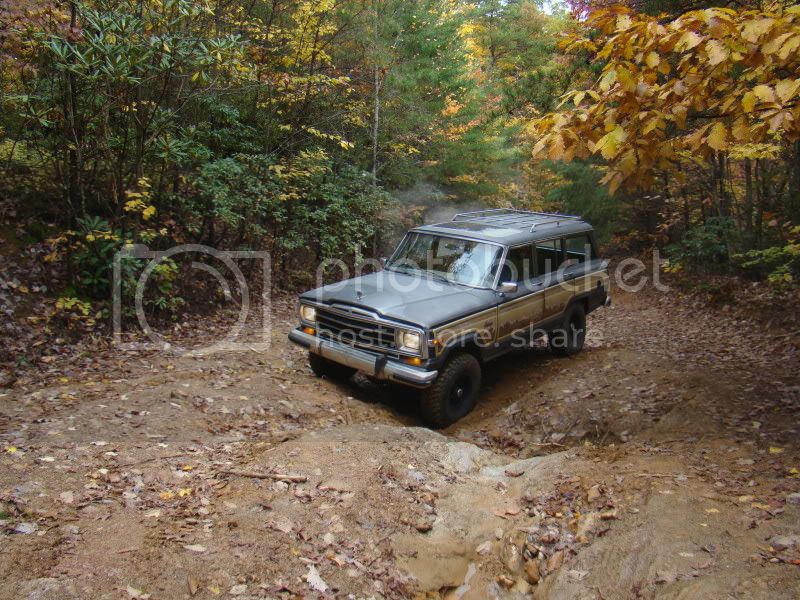

Bertha is her name and she's the '86 Grand Wagoneer that my wife has owned since '95 - their relationship is older than ours

We've been making strides over the last 2 years to get her trail ready and a little more reliable. It all started with a set of tires that she won at a cruiser raffle of all things - 33x10.5 BFG M/T's. We installed a 4" suspension lift from BJ's Offroad to make 'em fit. This also necessitated a little fender trimming in the rear.

Somewhere here in the middle we bought a used tranny (TF727) and had her rebuilt and acquired a NP208 transfer case that needed rebuilding. We decided to rebuild the 208 ourselves and it was pretty straight forward. Surprisingly it was in great shape and all we had to do was disassemble, clean up and reassemble.

Then we upgraded the carb with an Edelbrock Performer 1406 and matching intake manifold. I think she shed about 100lbs with this improvement. The old intake was boat anchor. In the process we desmogged her and got rid of a lot of unnecessary vacuum lines and bean cans.

OLD STUFF

NEW STUFF

She went on a couple wheeling trips and did pretty well on the trail.

Then we had an incident at Mountainside involving exploding driveshaft yokes.

Tom Woods to the rescue!

We've been making strides over the last 2 years to get her trail ready and a little more reliable. It all started with a set of tires that she won at a cruiser raffle of all things - 33x10.5 BFG M/T's. We installed a 4" suspension lift from BJ's Offroad to make 'em fit. This also necessitated a little fender trimming in the rear.

Somewhere here in the middle we bought a used tranny (TF727) and had her rebuilt and acquired a NP208 transfer case that needed rebuilding. We decided to rebuild the 208 ourselves and it was pretty straight forward. Surprisingly it was in great shape and all we had to do was disassemble, clean up and reassemble.

Then we upgraded the carb with an Edelbrock Performer 1406 and matching intake manifold. I think she shed about 100lbs with this improvement. The old intake was boat anchor. In the process we desmogged her and got rid of a lot of unnecessary vacuum lines and bean cans.

OLD STUFF

NEW STUFF

She went on a couple wheeling trips and did pretty well on the trail.

Then we had an incident at Mountainside involving exploding driveshaft yokes.

Tom Woods to the rescue!

Last edited: