Hello Mud,

I am taking a little brake from my main project to focus on something that has been nagging me for a long time. My trusty old 2nd gen Ram work truck's crappy always locked hubs.

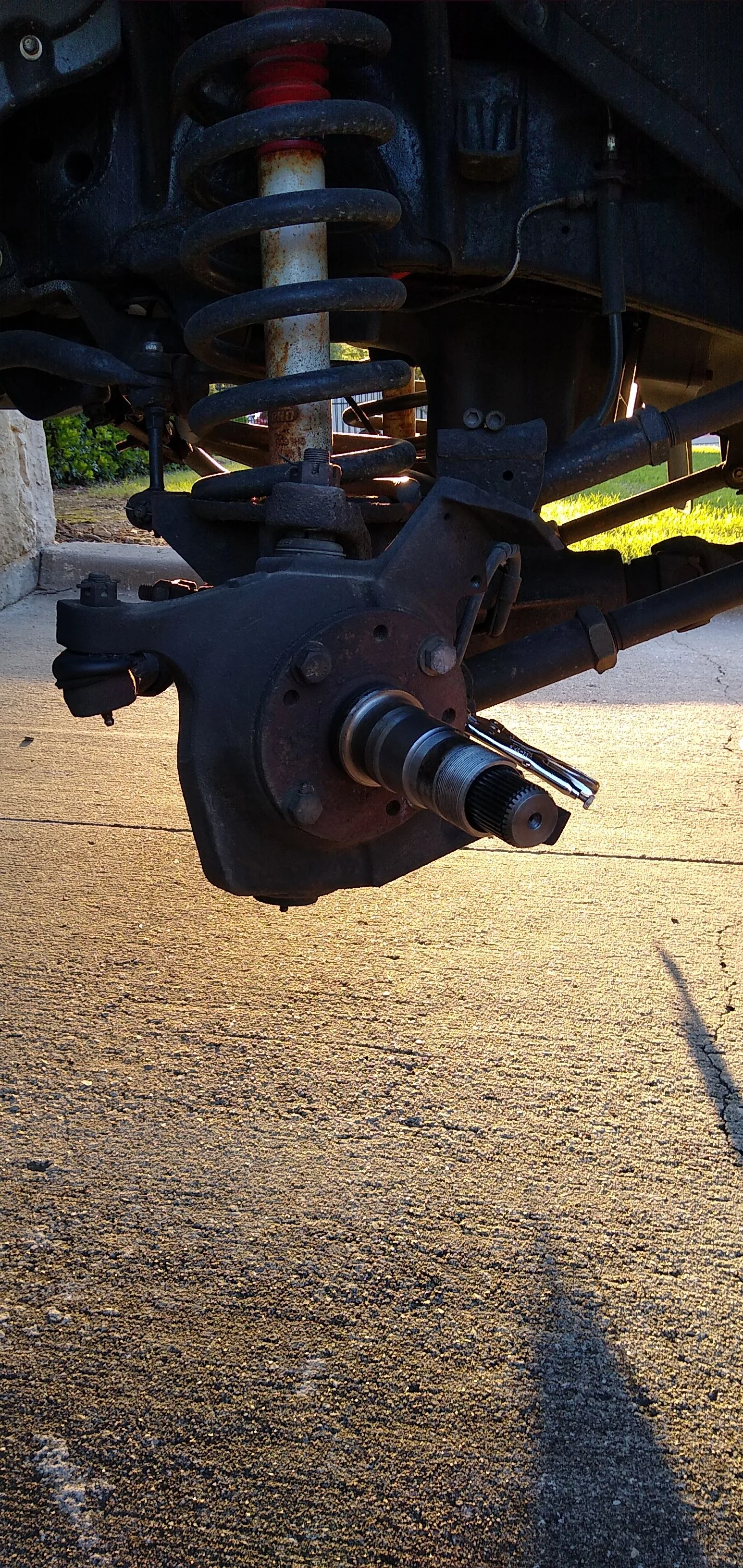

I currently have redrilled ford spindles on my front axle, which has increase WMS to WMS distance by 1.5 inches. The set up is ok but for the life of me I cannot get accurate info on the axle/spindle seals. Nothing I have tried to date has worked correctly. On a fundamental level I prefer tapered roller bearings, but this set up is just such a hack job that its gotta go.

Ford stubs and spindles boxed up.

For anyone who has access to these parts and can fab and weld to cast iron you can mount chevy p30 14.5 inch rotors to these hubs, but you would need to modify the dodge knuckle and fab a caliper bracket. Honestly for those of us crazy enough to still keep these old workhorses going I would lean more in the direction of a full axle swap, just to keep everything stock and serviceable. A dana 60 from a new super duty or perhaps a super 60 would be ideal. If I ever have a workshop again this will be something i'll look at.

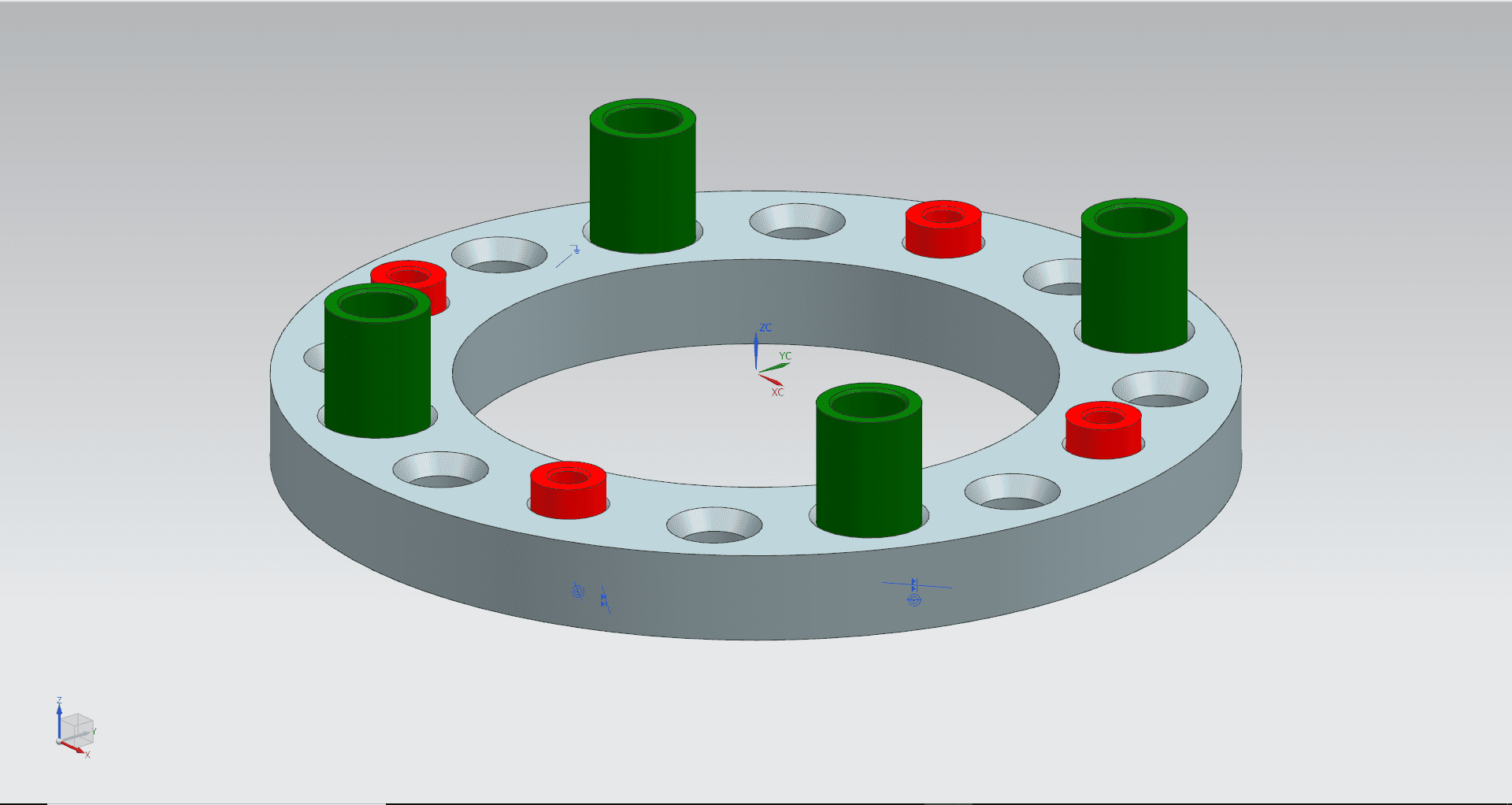

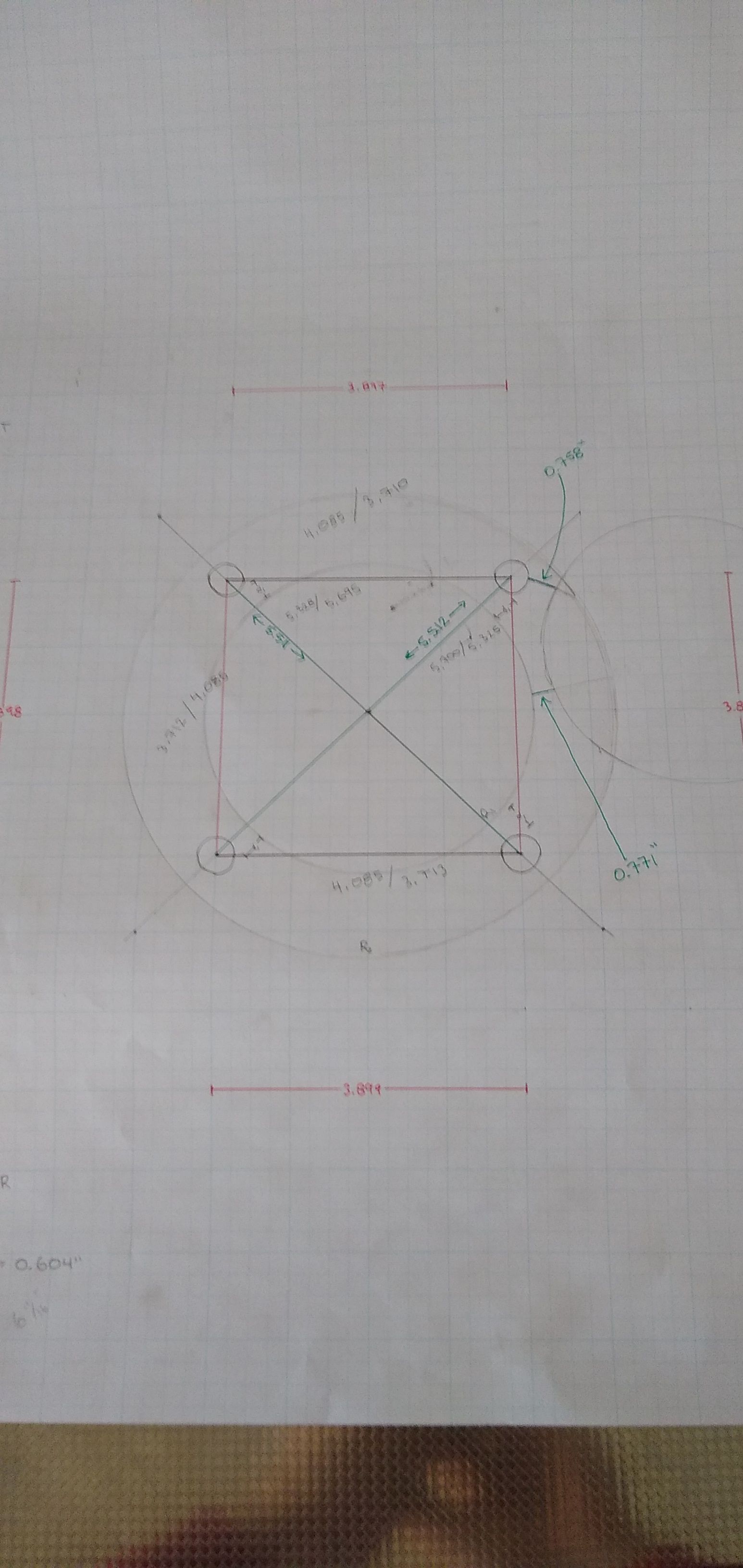

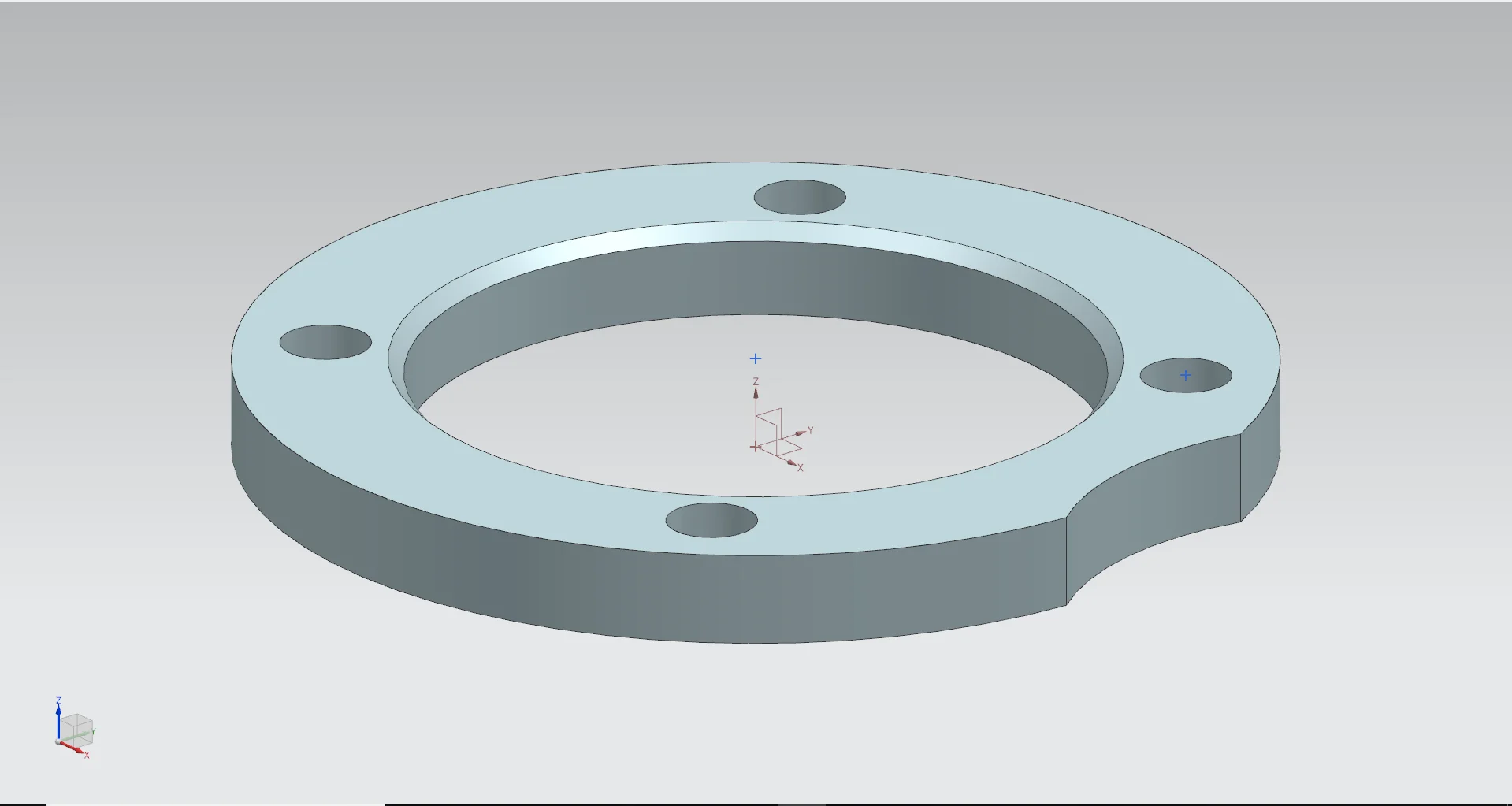

I am seeking an alternative, something that keep the WMS distance stock or close enough that the wheels don't stick past the sheet metal. I am going to attempt to install 2000 F-350 stub shafts along with the corresponding wheel hub assemblies. To combat the problem of the wheel lug pattern I have designed a fixture that should allow me to redrill the hub flange from the Ford to accept the 8x6.5'' pattern that the old dodges use.

I figured some of y'all would get a kick out of this since I bet I am not the only one who uses one of these rigs for dirty work. I hope I have not gotten in over my head, time will tell if my idea works.

I am taking a little brake from my main project to focus on something that has been nagging me for a long time. My trusty old 2nd gen Ram work truck's crappy always locked hubs.

I currently have redrilled ford spindles on my front axle, which has increase WMS to WMS distance by 1.5 inches. The set up is ok but for the life of me I cannot get accurate info on the axle/spindle seals. Nothing I have tried to date has worked correctly. On a fundamental level I prefer tapered roller bearings, but this set up is just such a hack job that its gotta go.

Ford stubs and spindles boxed up.

For anyone who has access to these parts and can fab and weld to cast iron you can mount chevy p30 14.5 inch rotors to these hubs, but you would need to modify the dodge knuckle and fab a caliper bracket. Honestly for those of us crazy enough to still keep these old workhorses going I would lean more in the direction of a full axle swap, just to keep everything stock and serviceable. A dana 60 from a new super duty or perhaps a super 60 would be ideal. If I ever have a workshop again this will be something i'll look at.

I am seeking an alternative, something that keep the WMS distance stock or close enough that the wheels don't stick past the sheet metal. I am going to attempt to install 2000 F-350 stub shafts along with the corresponding wheel hub assemblies. To combat the problem of the wheel lug pattern I have designed a fixture that should allow me to redrill the hub flange from the Ford to accept the 8x6.5'' pattern that the old dodges use.

I figured some of y'all would get a kick out of this since I bet I am not the only one who uses one of these rigs for dirty work. I hope I have not gotten in over my head, time will tell if my idea works.

Last edited: