I've been chugging along on my 1970 V8 build and it's time to do the electrics. None of the existing system is salvageable (I don't know what the PO did, but whatever it was didn't involve fuses) so it's a total rebuild. I have a strong background in low voltage electric and everything going back into the system is LED or limited high current devices .

Here's the rub.

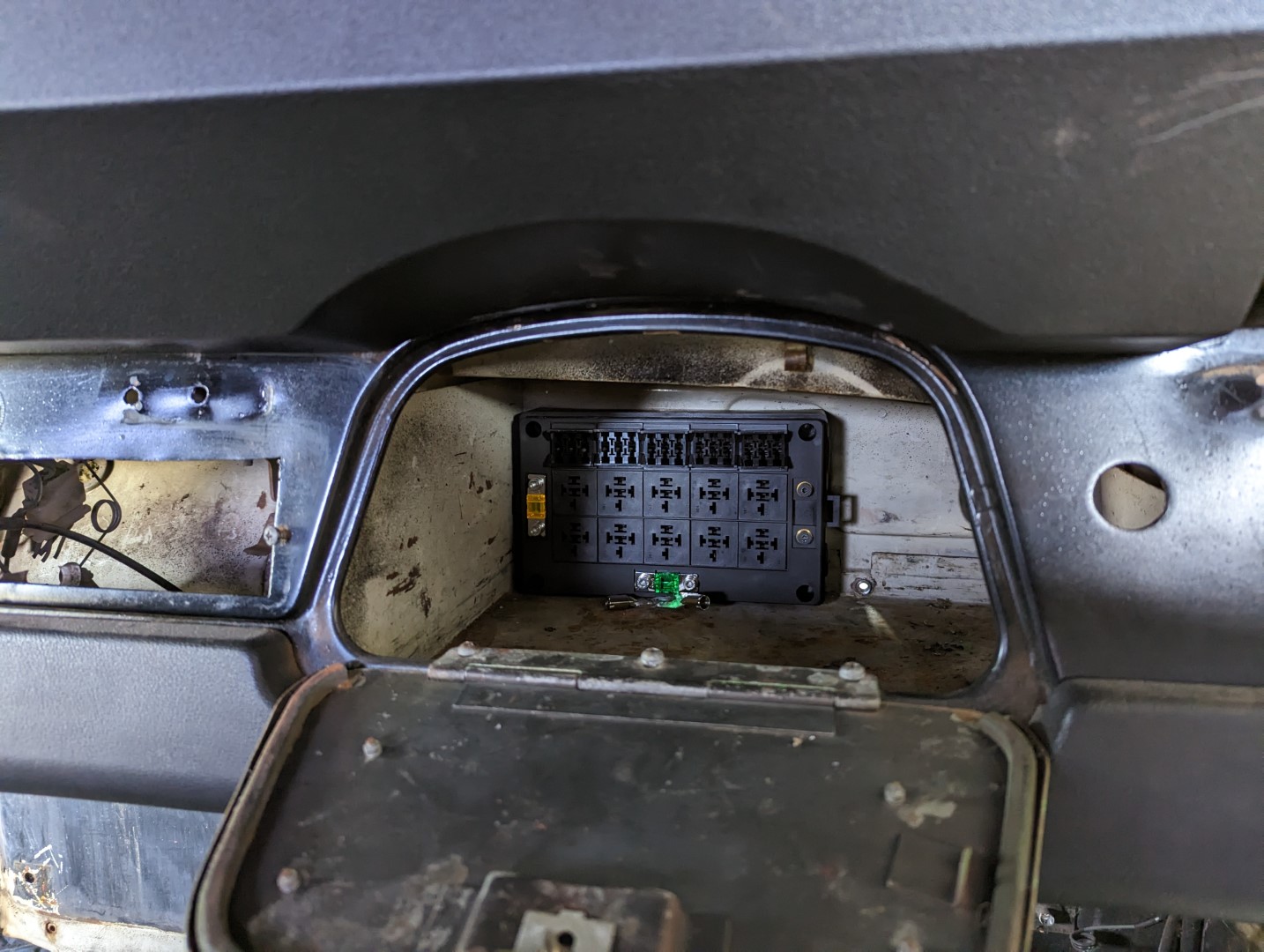

My brain tells me if it has a fuse, it has a relay, but every single harness I look it has maybe a handful of relays at best where I'm looking at somewhere around 12 after you account for the lights, blowers, horn, etc. I know that the current load should be well within range of what a dash switch can handle, but it feels wrong not to relay a load, even though it makes things more complex, costly and difficult to wire, albeit it not excessively.

If it was you, and you are starting from scratch, what would you do?

Here's the rub.

My brain tells me if it has a fuse, it has a relay, but every single harness I look it has maybe a handful of relays at best where I'm looking at somewhere around 12 after you account for the lights, blowers, horn, etc. I know that the current load should be well within range of what a dash switch can handle, but it feels wrong not to relay a load, even though it makes things more complex, costly and difficult to wire, albeit it not excessively.

If it was you, and you are starting from scratch, what would you do?