Hi all, I came across this mod for the VE pump:

What is a Boost Ring & do they work on Land Rovers? | 4Mud

How to install a Dynamic Timing Advance Spacer kit | Steg's Supplies

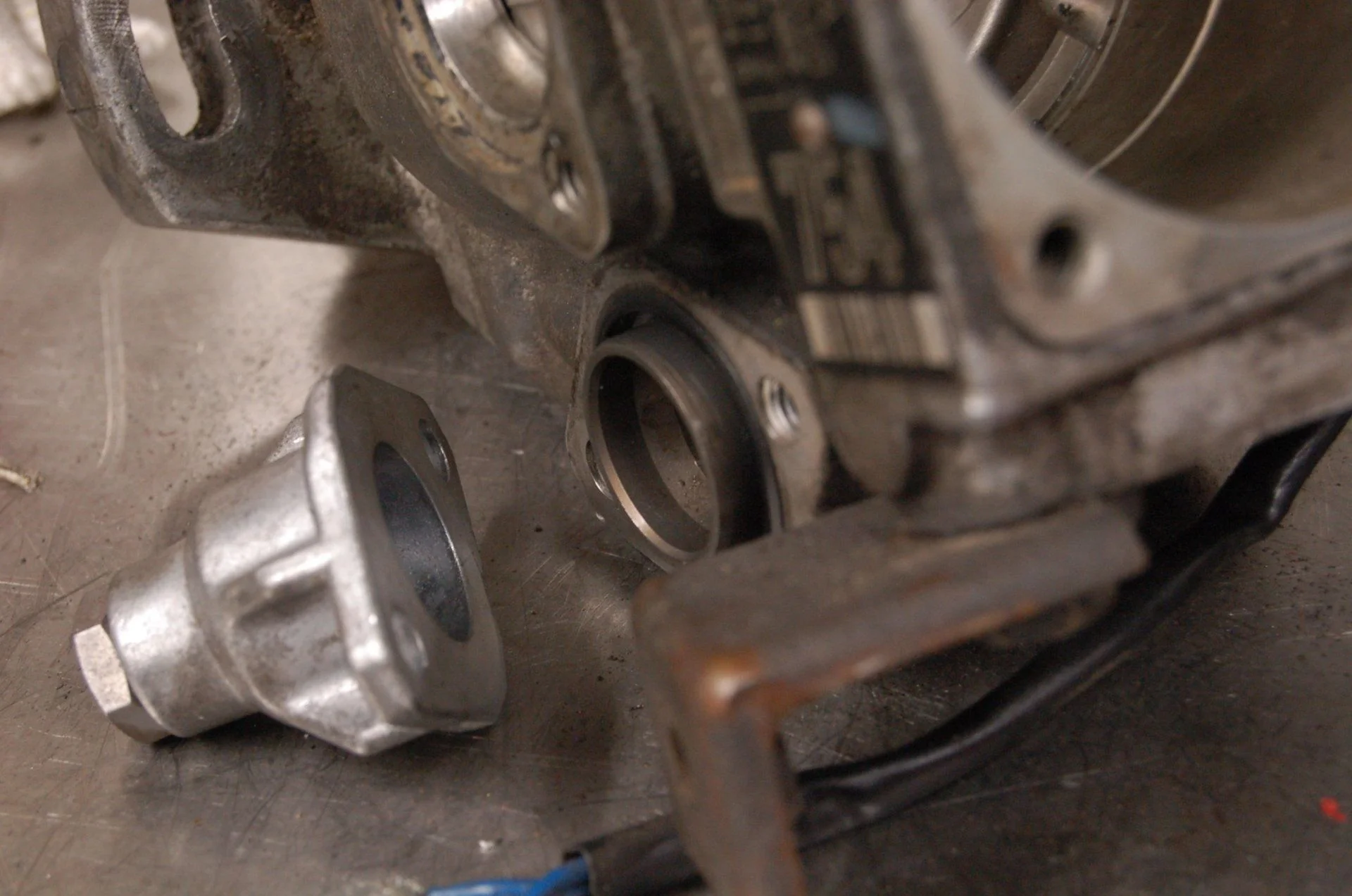

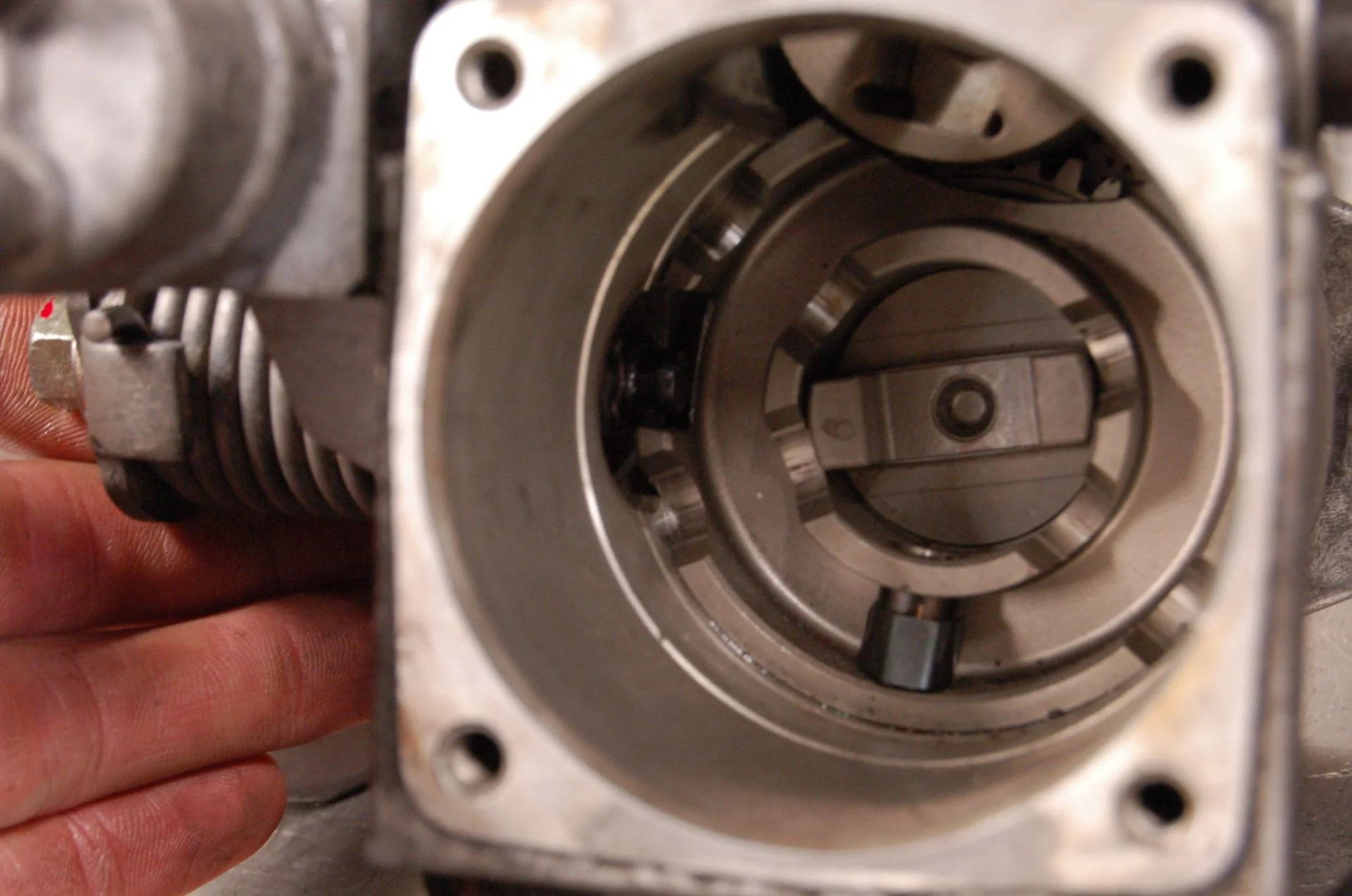

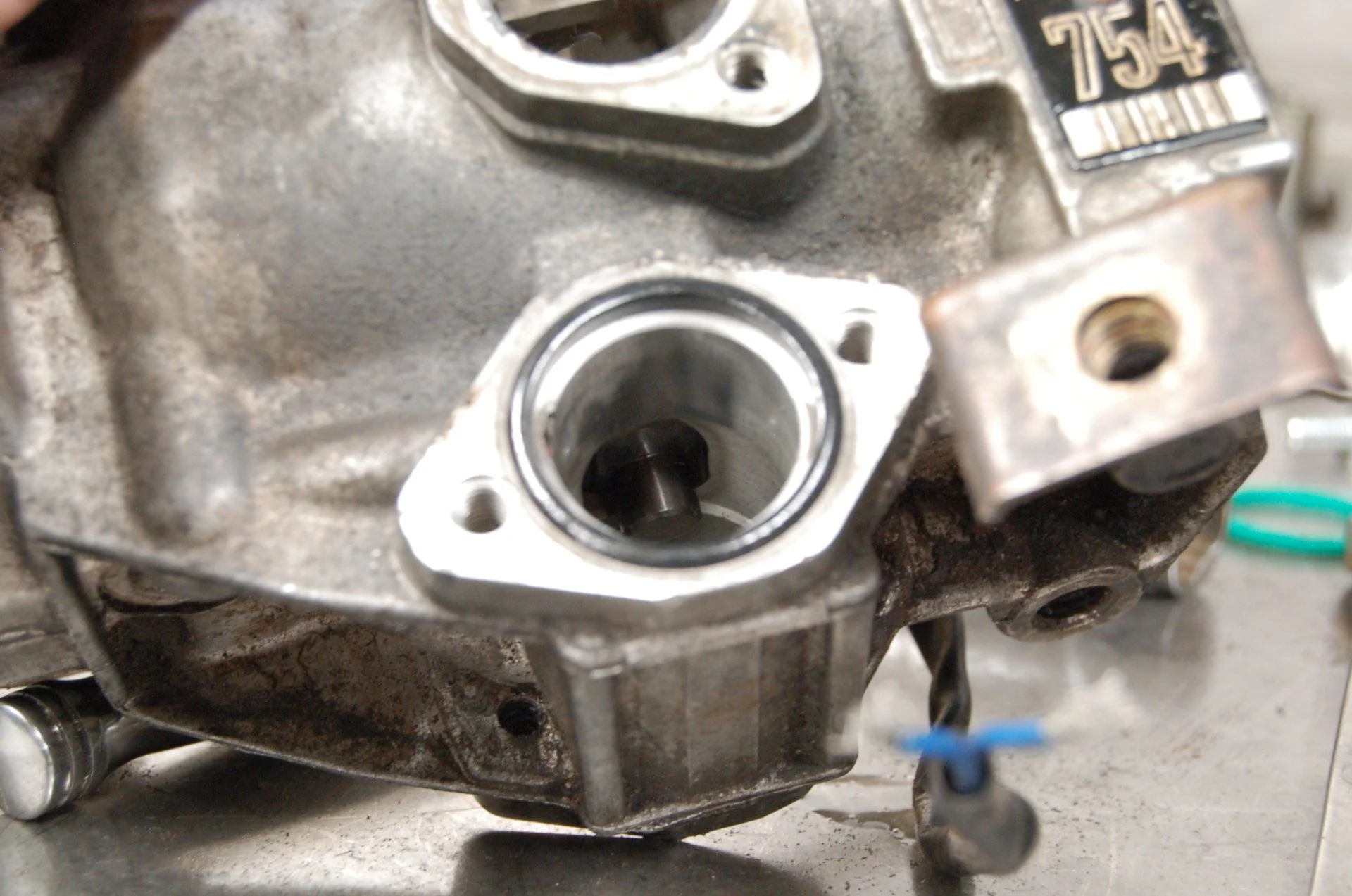

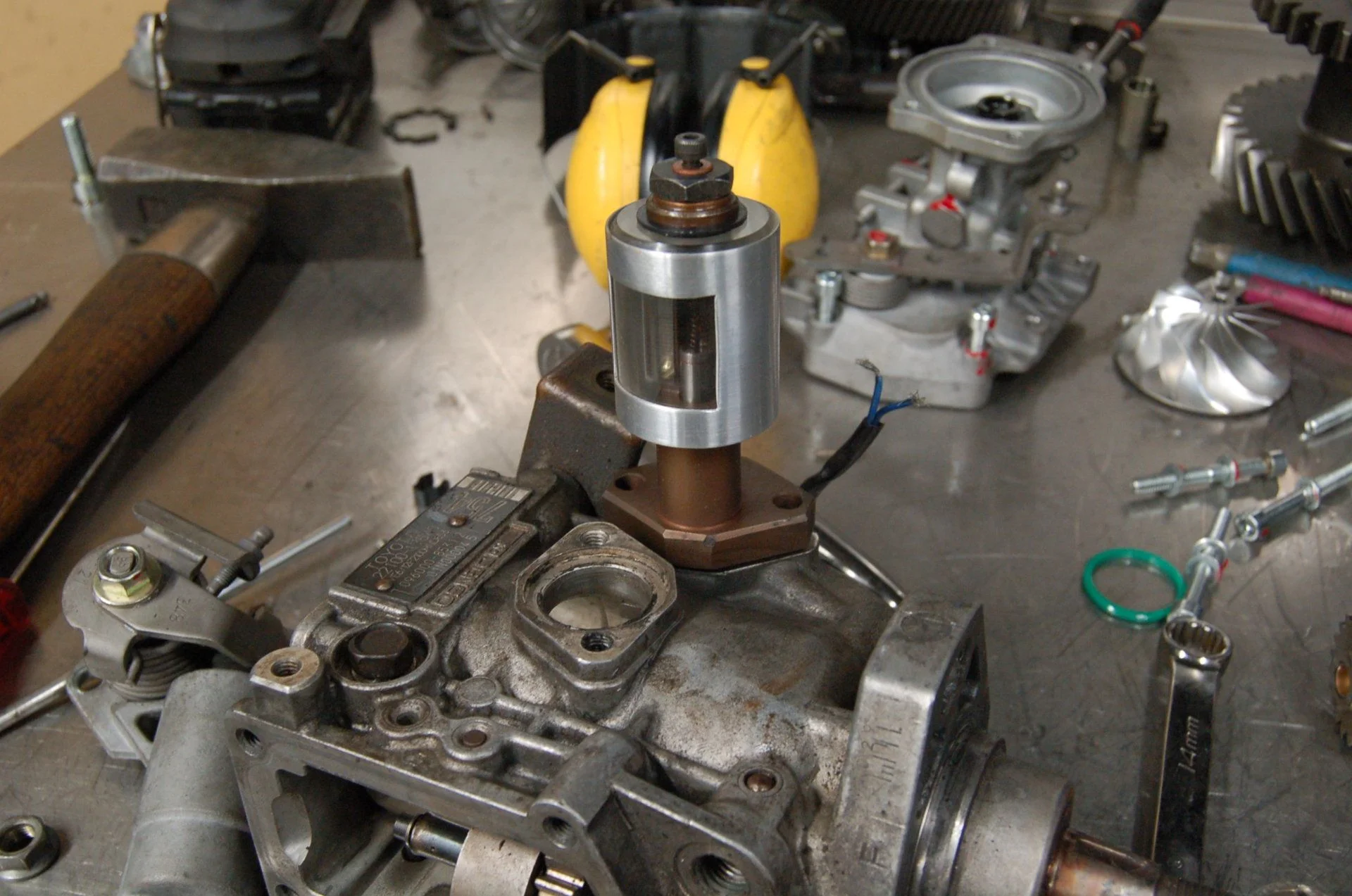

Basically it is a spacer that gives more travel to the dynamic advanced timing plunger in the pump wich advances the timing at higher revs for a better combustion.

Apparently it is a popular mod with the cummins and landrover crowd.

I also noticed my 1HDFT pump has an adjusting screw there.

Anyone have done this mod or played with the adjusting screw?

What is a Boost Ring & do they work on Land Rovers? | 4Mud

How to install a Dynamic Timing Advance Spacer kit | Steg's Supplies

Basically it is a spacer that gives more travel to the dynamic advanced timing plunger in the pump wich advances the timing at higher revs for a better combustion.

Apparently it is a popular mod with the cummins and landrover crowd.

I also noticed my 1HDFT pump has an adjusting screw there.

Anyone have done this mod or played with the adjusting screw?