davidp14

SILVER Star

It was hot AF today in Austin, so I didn't get out in the garage until after the sun went down. Made a little bit of progress while waiting on items to get back from powder-coater.

I used the flex-plate inspection access to put a 14mm deep impact socket on the flex plate bolt and immobilize the crank. Then used this badass 3/4" drive 38" long breaker bar to loosen the 33mm crank bolt. It was still pretty difficult to loosen. Can't imagine doing it with a smaller breaker.

I also noticed that I am randomly missing a bolt on the transmission bell housing.

I was able to follow this badass writeup and remove the oil pump cover plate (How to Replace Oil Pump seal w/ Pics). Used a #3 JIS bit, small hammer, and a 1/4" socket. They came out without a hiccup, which I was very pleased with.

d

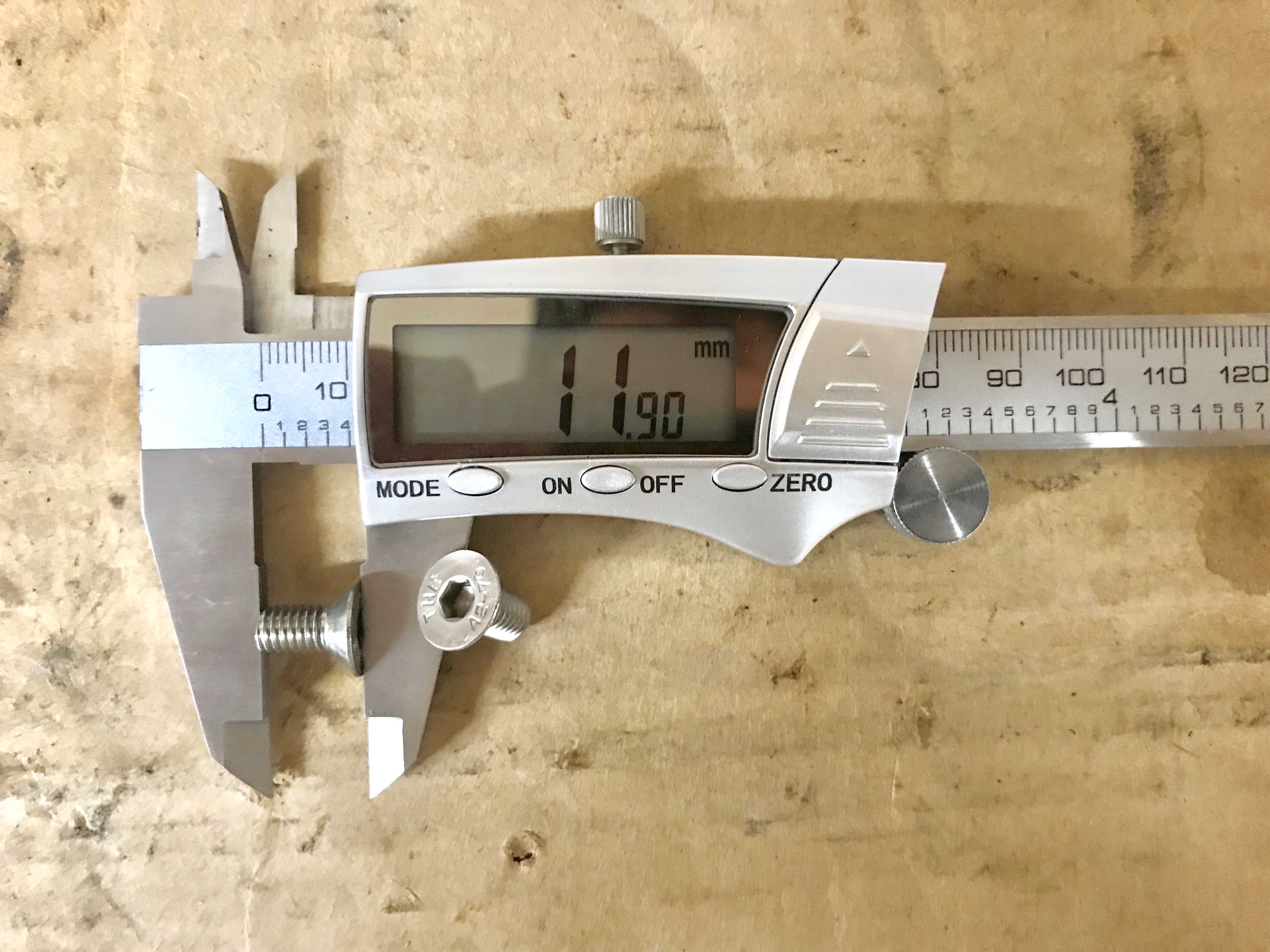

Finally, I took the opportunity to compare the OEM JIS screws with some stainless Allens I had.

The OEM screws are about 13.45mm

The M6 stainless Allen bolts I had were just a hair under 12mm.

Obviously on such a short fastener, thread engagement is important. But I can't imagine the oil pump cover sees much load.

At this point I'm not sure if I am going to replace them with new OEM screws, or aftermarket stainless torx/allens. In the perfect world I would use M6x1.0 flathead stainless steel torx that are exactly 13.45mm long. Finding flathead stainless steel M6 torx is a tall order in itself. Let alone 13.45mm long, which is an uncommon size.

nice work van! where'd you get that BF breaker bar? my minuscule 1/2 breaker is the only thing keeping from doing my front main and oil pump seal right now. Im worried that the HF one is too short. this is probably the only job it will ever have though so i dont want to spend a bunch of $$ on a one and done tool.

btw i ordered a flexi head seal puller from amazon..saw it in OTRAMM's vid. havent used it but it might be the ticket to get the seal out....i hope