- Thread starter

- #101

I'm adding the 12volt conversion to the "to-do some day" list. When? Who knows.

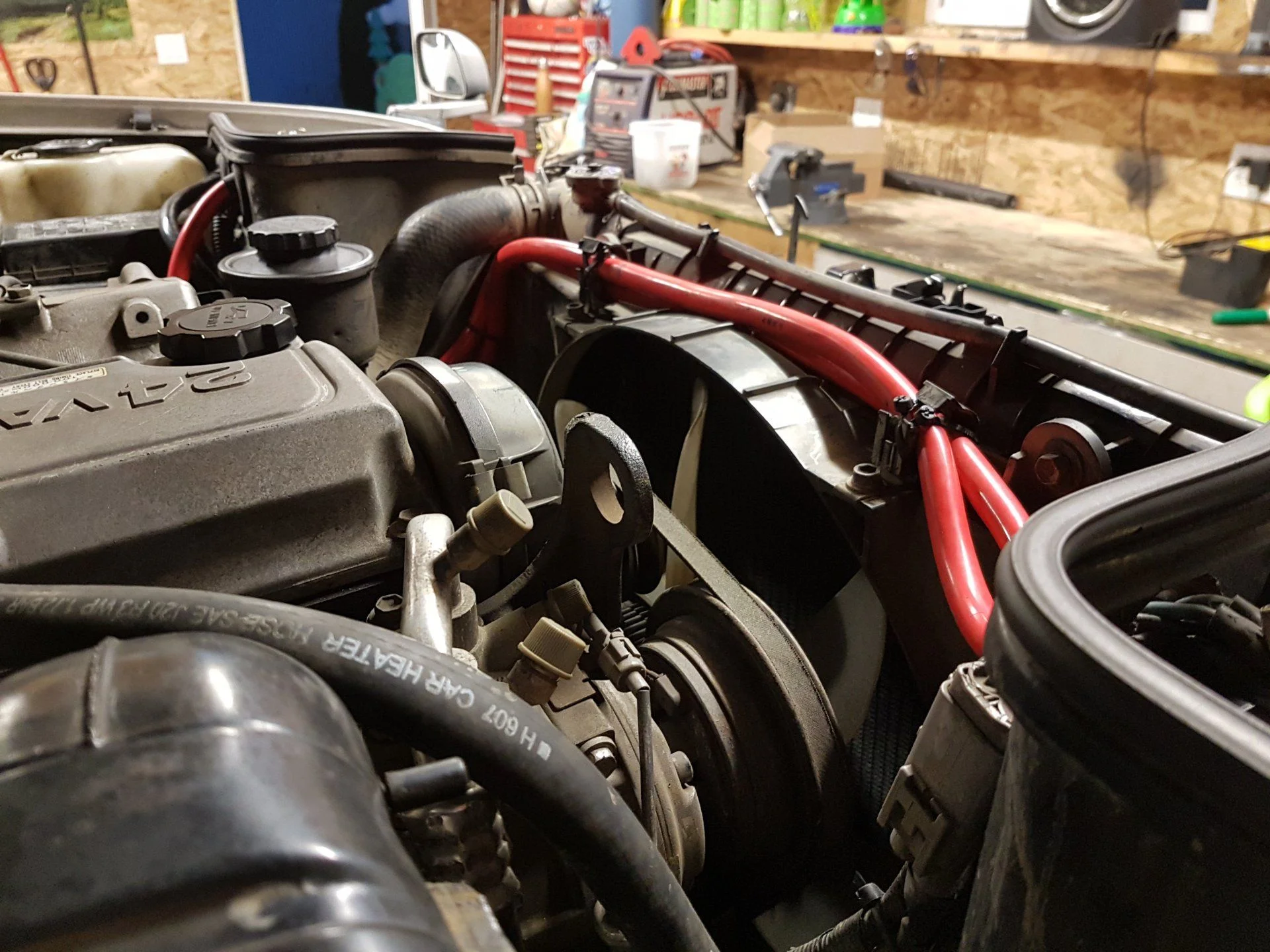

For now though I found an evening without previous commitments so i put some new copper in there.

That poor angle shows some new 1/0 copper wiring: alternator to battery1, battery1 to relay, battery2 to relay, relay - to block, battery 2- to block.

Didn't solve a damn thing.

But, they are in there now and nothing wrong with that.

My dumb lazy ass still hasn't borrowed a DC clamp so i don't know if things are pulling current or something else is up. The alt just barely puts out a voltage above the resting volts of the batteries, then it warms up and seems happy. Maybe takes 30 seconds to a minute. Very slight, almost imperceptible waver of the voltmeter in the truck when blinkers are on, etc, otherwise all seems fine.

Le sigh...

For now though I found an evening without previous commitments so i put some new copper in there.

That poor angle shows some new 1/0 copper wiring: alternator to battery1, battery1 to relay, battery2 to relay, relay - to block, battery 2- to block.

Didn't solve a damn thing.

But, they are in there now and nothing wrong with that.

My dumb lazy ass still hasn't borrowed a DC clamp so i don't know if things are pulling current or something else is up. The alt just barely puts out a voltage above the resting volts of the batteries, then it warms up and seems happy. Maybe takes 30 seconds to a minute. Very slight, almost imperceptible waver of the voltmeter in the truck when blinkers are on, etc, otherwise all seems fine.

Le sigh...