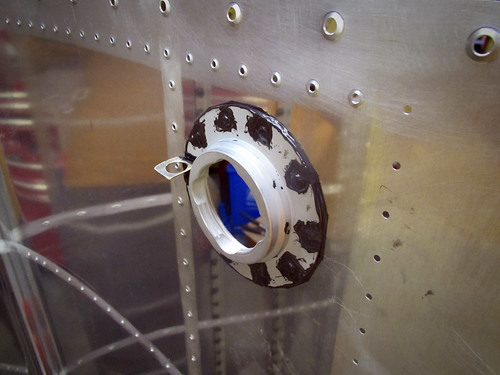

I have an Aluminum fuel cell in my 60.

The fuel pressure sender and the fuel pump flange are both barely seeping. Which is letting the inside cab of my 60 smell on hot days.

Anyone have a lead on some self leveling stuff that I can drizzle on the sending unit and the fuel pump flange to seal it up? I know it exists, because I have seen it on race cars. But for soem reason my interweb skills bring the suck right now..

The idea is kind of like the self leveling sealant used on the top of motorhomes, but is fuel safe.

The fuel pressure sender and the fuel pump flange are both barely seeping. Which is letting the inside cab of my 60 smell on hot days.

Anyone have a lead on some self leveling stuff that I can drizzle on the sending unit and the fuel pump flange to seal it up? I know it exists, because I have seen it on race cars. But for soem reason my interweb skills bring the suck right now..

The idea is kind of like the self leveling sealant used on the top of motorhomes, but is fuel safe.