alia176

SILVER Star

My truck was a weekend wheeler and I knew it consumed oil, but didn’t care. Now it has been my daily for almost 2 years or so? I stopped tracking fuel fill-ups and moved to tracking oil fill-ups. I am averaging 1qt every 500-650 miles.

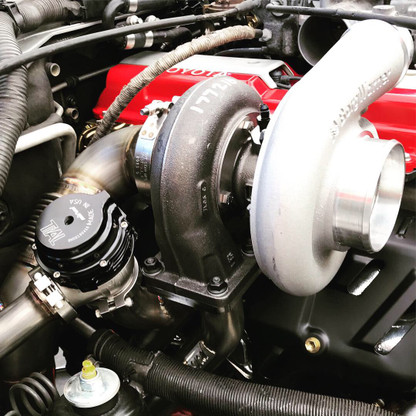

Is it “necessary“ to address this for a turbo install? If it is, I will save for a head rebuild and a short block. If not, I will just keep adding oil, as the truck runs fantastic.

You brought up an interesting point. I'm in the middle of replacing the front main seal, even though it's only less than 10 years old. I know the syn oil is partially responsible but I also wonder if my PCV isn't working properly and the crankcase is getting pressurized? I dunno, just a WAG at this point. But, I'll remove the valve cover to do the seal as a PM and also check that one PCV with baffle (valve cover has two PCVs) while I have it off the head.