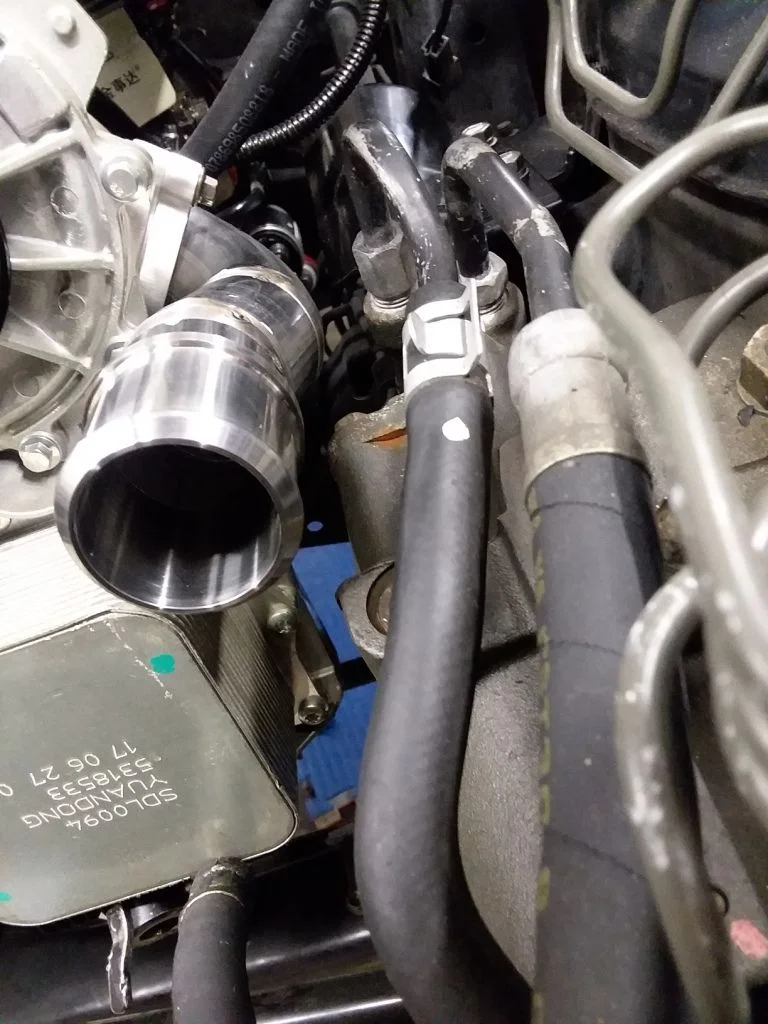

I don't have any pics of my own swap since I'm still getting things ready for the swap (lift, dual batteries, hydroboost), and haven't pulled the gasser out yet, but here are some pics of a stock FJ60 radiator and stock isuzu 4BD2T intercooler in an 80.

Builds - Isuzu 4BD1T Lexus LX450 (Land Cruiser) Build

Builds - Isuzu 4BD1T Lexus LX450 (Land Cruiser) Build

Builds - Isuzu 4BD1T Lexus LX450 (Land Cruiser) Build

Switching my 97LC-4bt swap to Isuzu 4bd1t

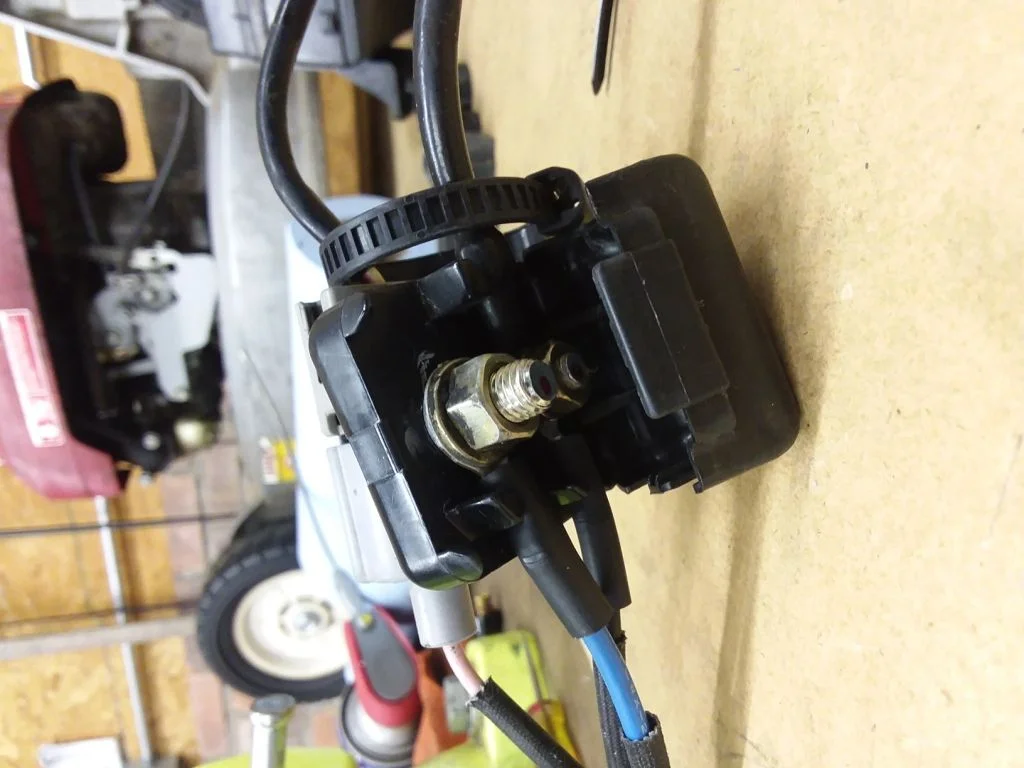

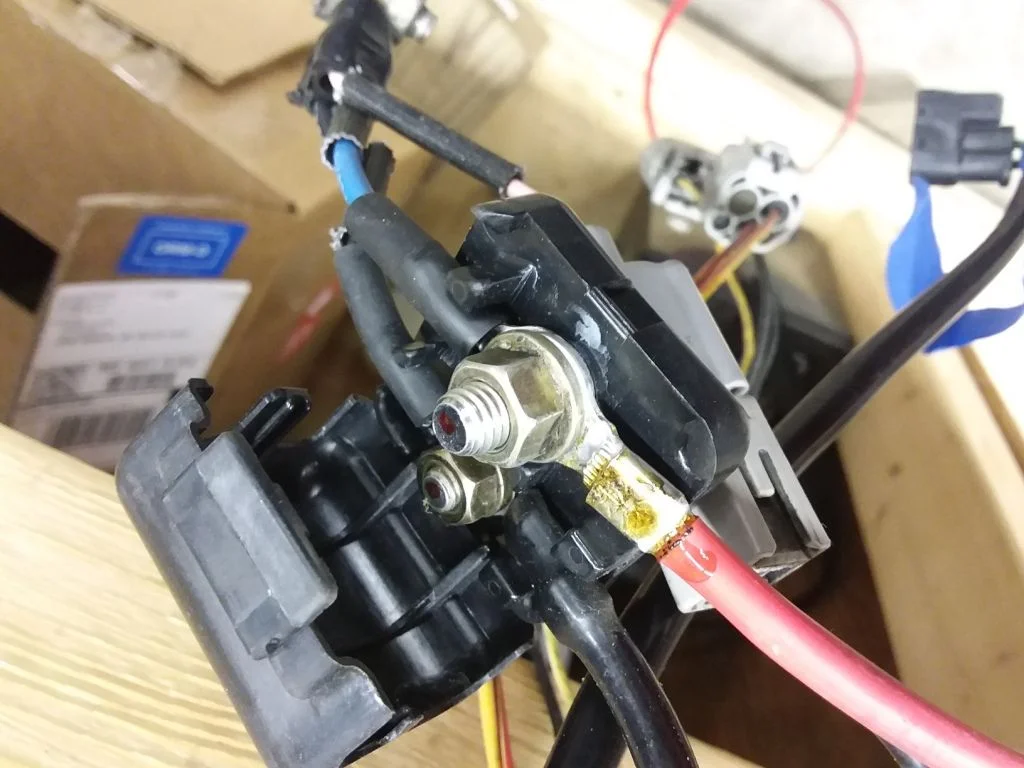

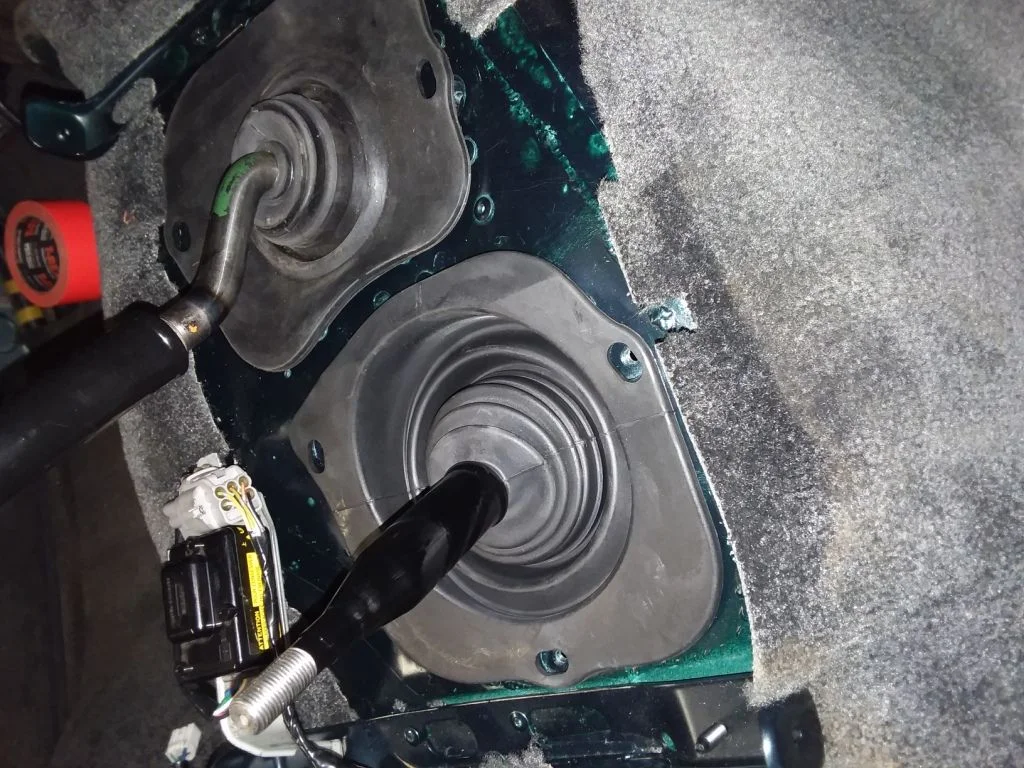

Budget 4bd1t -> '94 FZJ80 Build

Budget 4bd1t -> '94 FZJ80 Build

Builds - Isuzu 4BD1T Lexus LX450 (Land Cruiser) Build

Builds - Isuzu 4BD1T Lexus LX450 (Land Cruiser) Build

Builds - Isuzu 4BD1T Lexus LX450 (Land Cruiser) Build

Switching my 97LC-4bt swap to Isuzu 4bd1t

Budget 4bd1t -> '94 FZJ80 Build

Budget 4bd1t -> '94 FZJ80 Build