EPIC Cruisers

Supporting Vendor

Hello everyone,

I think I should start by introducing myself and my rig. I purchased my 1997 LX 450 (triple locked w/160K) a few months ago with plans to turn it into an overlanding/camping rig. I'm new to the Land Cruiser world but I'm a huge car guy. Besides the LX I have 2 BMWs, a 1983 528e and a 2007 335xi, along with a Yamaha R3. The old BMW is my baby and the car that taught me how to work on cars. I've restored it mechanically and it was my daily driver up until I bought the LX. The two others are more of my toys and I drive them a week at a time every once in awhile. I'm an Industrial Designer by schooling but an Engineer by profession so needless to say I enjoy taking things apart and fixing them.

I wanted to start this thread as a way to document my "build" and post pictures of cool places I will hopefully discover with the LX.

Here goes nothing...

Initially I was not looking for an 80 series, but instead I was looking for something more affordable around the $2-4K mark. I liked the 80 series styling but I didn't want to spend 80 series money on my first rig. Well that quickly changed when I was searching Facebook Marketplace when I saw this 161,000 mile triple locked LX about 2.5 hours from my town. Originally listed at $8K. The owner didn't state it was triple locked but there was a picture showing the switch.

I asked the owner for some more pictures and service history out of curiosity. He said he'd send pictures and any history he had later that week. The week passed and I didn't get anything from him so I sent him another message. He responded by saying he didn't have a chance to take them but that he needed to sell it asap and that he'd be willing to sell it for less that weekend. I was a little weary so I asked for the VIN and ran a CarFax on it. Everything came back good and it showed it was a SC/NC car all its life. With one visit to a VA dealer. His grandfather had been the owner for the last 13 years. Seeing all this I made an offer I thought he would refuse, but said I would only pay that amount if there were absolutely no big issues with it once I looked at it. He said that would work. Honestly I was surprised and still weary. I told him I'd meet him the following day to take a look.

I stayed up the rest of that night doing research and writing a list of things to look for when buying an 80 series. From that research, I concluded that my main concerns should be the coolant system and front axle maintenance. Every other common issue seemed to be a part of owning any older vehicle, so I wasn't worried about anything else. I called my dad that night and asked him to come with me, the following day we drove down to a small SC town 2.5 hours from our hometown. I was still a little weary up to this point because of how eager he was to sell it. However, once I met the guy I was a little more comfortable. He has a firefighter and seemed like a good ole country boy. Nice guy. He honestly didn't know much about the 80 because he kept calling it a Jeep, he later told me his grandfather (a lawyer) had given it to him and he had no need for it. However, he needed the money for personal reasons.

I asked him about the service history and he said that he didn’t have any documentation but that a local shop did any work needed. So I started carefully looking over the rig, the body/paint was flawless but there was some paint flaking off the rear bumper and the door trim. All the VIN numbers on the panels matched. Mechanically I noticed that the valve cover gasket was leaking, the knuckles were covered in grease, and that the coolant system didn’t look great. There was green coolant in it and there was a lot of brown deposit’s in the radiator. I proceeded to test drive it and test all the common features. Everything worked, including the “D” light on the dash, oddly enough the backlight for the shifter was burn out though. Most importantly it did in fact have lockers and they seemed to work properly.

After the test drive I spoke to him and told him that there were some issues with the vehicle and that I would offer him $800 less than our previously discussed price. He asked if I could do a little more and I stood firmly by my price seeing that I would have to invest a good bit of money in it. After a few minutes, he agreed to my price. Looking back on it now I got it for an amazing price considering I could sell it at its current state now for 2-3 times the price I paid for it. He signed over the title and I was the proud new owner of a triple locked, 161,000 mile 1997 Lexus LX450!!!

I proceeded to drive it home without any issues on the 2.5 hour trip back home. I continued driving it to work for a couple weeks and fell in love with it. I was starting to have issues with the battery draining if left sitting an entire day. I looked at the battery and noticed that it was 8 years old, I replaced it and the draining issue was solved.

Eventually I started ordering parts to baseline the rig. I ordered a OES valve cover gasket kit, distributor OEM o-ring, knuckle rebuild kit from Cruiser Outfitters, new front rotors, new Koyo trunnion bearings, new Koyo wheel bearings, new OEM thermostat, new Denso sparkplugs, new OEM wires, new OES distributor cap, and a new OEM rotor button. I had some left-over silicone vacuum hose from my BMWs but needed some additional 6mm hose for the bigger hoses on the 80. I ordered a couple more feet of the silicone vacuum hose. Lastly I purchased some 5/8” Gates Green Stripe hose from O’Reillys for the heater hoses and some 1/2 “ from Wits’end, since he’s the only person that sells it by the foot. I also ordered some Breeze constant torque #10 clamps.

By the way, I ordered from Wits’end right before Christmas/New Years and wanted the hose to be in before then so I could knock out all this maintenance during my time off. I gave Joey a call and he told me he would make sure it would ship out asap so I would get it before the holidays. He later emailed me to let me know that he had shipped my package and that he was also refunding me some of the shipping cost because his website had overcharged me. Not only did he make sure I received my package before the holidays but he also was honest about me being overcharged. Very few people/businesses would do that nowadays so I thought I should mention it. Keep up the good work!

Once I had everything, I got to work…

Valve train looked great…

Wrapped up the wiring loom with Tesa tape (what BMW uses on their wiring looms). I will eventually replace this or add a heat sleeve to protect more from the heat…

I didn’t take any pictures of the knuckle job or other maintenance since it is heavily documented by others on the forum. I also flushed the coolant system at home as much as I could but it was in very poor shape with a lot of buildup. Once I put everything back together I took the 80 to a local radiator shop so they could pressure flush the coolant system in hopes of getting as much sediment out as possible. (Yes, this is foreshadowing of problems to come…)

After all this hard work I drove the 80 for a couple of months enjoying it and fixing little things here and there…

Changed the stripped seat gears…

Cleaned the contacts on my drivers window switch…

Dealt with clogged sunroof drains. I also added a thicker seal to a piece on the sunroof rail to stop water from coming into the headliner area.

I found the correct remote for my alarm system. I could not find anyone else with this FCC ID on their control box to figure out what remote to purchase. So I looked on other forums and made an educated guess at the correct remote, luckily I got it on the first try! If the FCC ID on your control box is BAB237000-128 then a remote with the FCC ID BAB237131-022 will work.

I replaced my broken antenna cable. Kinda a pain but can be done in about 20 minutes…

Replaced this exhaust mount…

I also replaced my front speakers with some Pioneer TS-G1645R and for the rears I used some Pioneer TS-G1045R. No pictures of this but they fit almost perfectly in the LX doors. I also installed a ScanGauge at the same time.

THE MOMENT YOU ALL HAVE BEEN WAITING FOR!!! After all this work and driving if about 2-3,000 miles the head gasket blew. You can read more about my head gasket story on this thread… No heat, overheating and coolant full??, my first post is #18. I thought about doing the head gasket job myself but honestly I didn’t have the time, space, or experience to do it. I decided to have Trollhole do it instead. They did an awesome job and documented everything. Marshall and Greg are very knowledgeable. We did have some small issues but they did everything in their power to make them right. I’ll detail those issues later.

I had the 80 towed on a flatbed to their shop about 1 hour from my house. These are engine bay shots of how they got it…

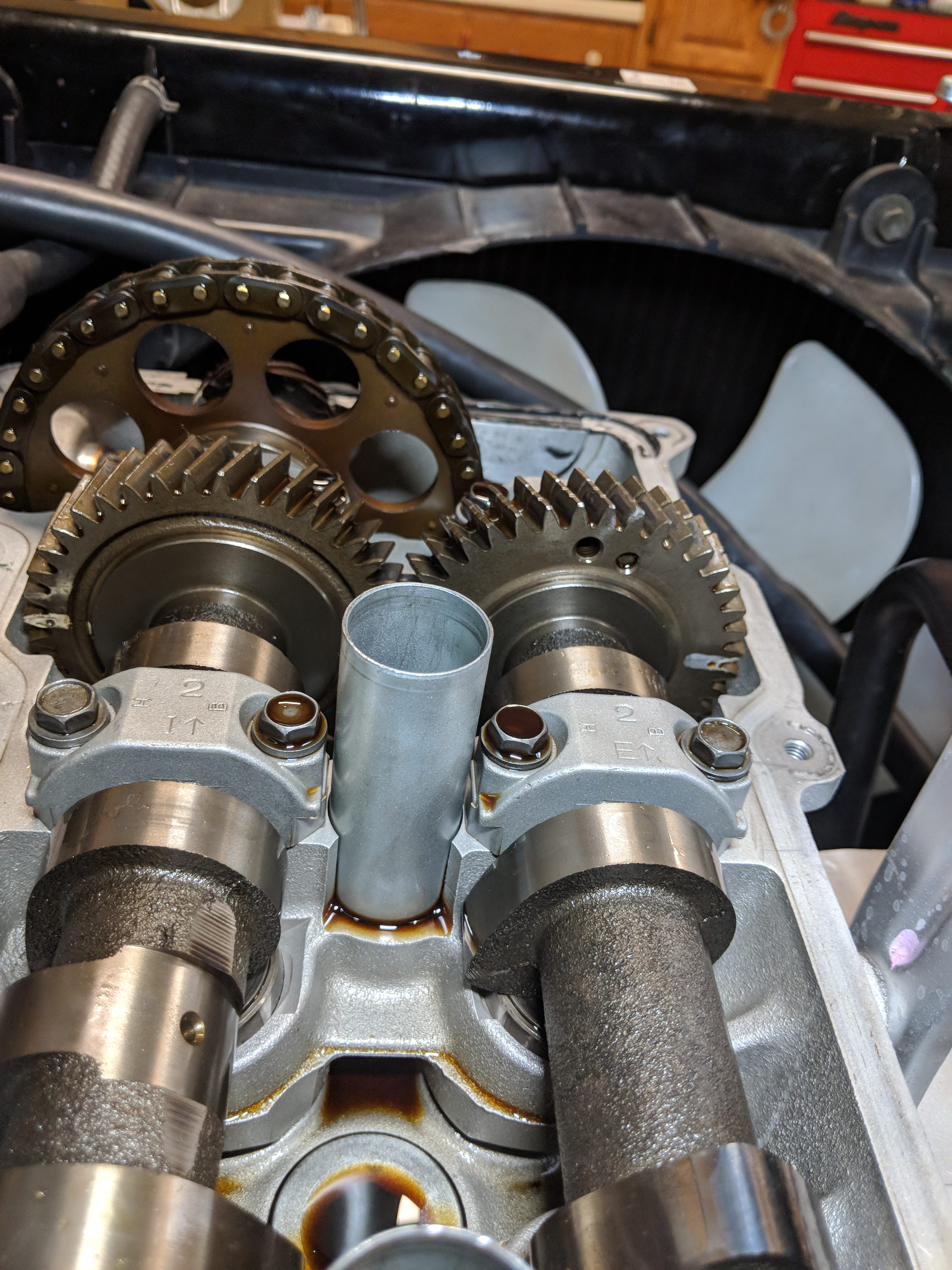

Camshafts coming out…

Head off…

I think I should start by introducing myself and my rig. I purchased my 1997 LX 450 (triple locked w/160K) a few months ago with plans to turn it into an overlanding/camping rig. I'm new to the Land Cruiser world but I'm a huge car guy. Besides the LX I have 2 BMWs, a 1983 528e and a 2007 335xi, along with a Yamaha R3. The old BMW is my baby and the car that taught me how to work on cars. I've restored it mechanically and it was my daily driver up until I bought the LX. The two others are more of my toys and I drive them a week at a time every once in awhile. I'm an Industrial Designer by schooling but an Engineer by profession so needless to say I enjoy taking things apart and fixing them.

I wanted to start this thread as a way to document my "build" and post pictures of cool places I will hopefully discover with the LX.

Here goes nothing...

Initially I was not looking for an 80 series, but instead I was looking for something more affordable around the $2-4K mark. I liked the 80 series styling but I didn't want to spend 80 series money on my first rig. Well that quickly changed when I was searching Facebook Marketplace when I saw this 161,000 mile triple locked LX about 2.5 hours from my town. Originally listed at $8K. The owner didn't state it was triple locked but there was a picture showing the switch.

I asked the owner for some more pictures and service history out of curiosity. He said he'd send pictures and any history he had later that week. The week passed and I didn't get anything from him so I sent him another message. He responded by saying he didn't have a chance to take them but that he needed to sell it asap and that he'd be willing to sell it for less that weekend. I was a little weary so I asked for the VIN and ran a CarFax on it. Everything came back good and it showed it was a SC/NC car all its life. With one visit to a VA dealer. His grandfather had been the owner for the last 13 years. Seeing all this I made an offer I thought he would refuse, but said I would only pay that amount if there were absolutely no big issues with it once I looked at it. He said that would work. Honestly I was surprised and still weary. I told him I'd meet him the following day to take a look.

I stayed up the rest of that night doing research and writing a list of things to look for when buying an 80 series. From that research, I concluded that my main concerns should be the coolant system and front axle maintenance. Every other common issue seemed to be a part of owning any older vehicle, so I wasn't worried about anything else. I called my dad that night and asked him to come with me, the following day we drove down to a small SC town 2.5 hours from our hometown. I was still a little weary up to this point because of how eager he was to sell it. However, once I met the guy I was a little more comfortable. He has a firefighter and seemed like a good ole country boy. Nice guy. He honestly didn't know much about the 80 because he kept calling it a Jeep, he later told me his grandfather (a lawyer) had given it to him and he had no need for it. However, he needed the money for personal reasons.

I asked him about the service history and he said that he didn’t have any documentation but that a local shop did any work needed. So I started carefully looking over the rig, the body/paint was flawless but there was some paint flaking off the rear bumper and the door trim. All the VIN numbers on the panels matched. Mechanically I noticed that the valve cover gasket was leaking, the knuckles were covered in grease, and that the coolant system didn’t look great. There was green coolant in it and there was a lot of brown deposit’s in the radiator. I proceeded to test drive it and test all the common features. Everything worked, including the “D” light on the dash, oddly enough the backlight for the shifter was burn out though. Most importantly it did in fact have lockers and they seemed to work properly.

After the test drive I spoke to him and told him that there were some issues with the vehicle and that I would offer him $800 less than our previously discussed price. He asked if I could do a little more and I stood firmly by my price seeing that I would have to invest a good bit of money in it. After a few minutes, he agreed to my price. Looking back on it now I got it for an amazing price considering I could sell it at its current state now for 2-3 times the price I paid for it. He signed over the title and I was the proud new owner of a triple locked, 161,000 mile 1997 Lexus LX450!!!

I proceeded to drive it home without any issues on the 2.5 hour trip back home. I continued driving it to work for a couple weeks and fell in love with it. I was starting to have issues with the battery draining if left sitting an entire day. I looked at the battery and noticed that it was 8 years old, I replaced it and the draining issue was solved.

Eventually I started ordering parts to baseline the rig. I ordered a OES valve cover gasket kit, distributor OEM o-ring, knuckle rebuild kit from Cruiser Outfitters, new front rotors, new Koyo trunnion bearings, new Koyo wheel bearings, new OEM thermostat, new Denso sparkplugs, new OEM wires, new OES distributor cap, and a new OEM rotor button. I had some left-over silicone vacuum hose from my BMWs but needed some additional 6mm hose for the bigger hoses on the 80. I ordered a couple more feet of the silicone vacuum hose. Lastly I purchased some 5/8” Gates Green Stripe hose from O’Reillys for the heater hoses and some 1/2 “ from Wits’end, since he’s the only person that sells it by the foot. I also ordered some Breeze constant torque #10 clamps.

By the way, I ordered from Wits’end right before Christmas/New Years and wanted the hose to be in before then so I could knock out all this maintenance during my time off. I gave Joey a call and he told me he would make sure it would ship out asap so I would get it before the holidays. He later emailed me to let me know that he had shipped my package and that he was also refunding me some of the shipping cost because his website had overcharged me. Not only did he make sure I received my package before the holidays but he also was honest about me being overcharged. Very few people/businesses would do that nowadays so I thought I should mention it. Keep up the good work!

Once I had everything, I got to work…

Valve train looked great…

Wrapped up the wiring loom with Tesa tape (what BMW uses on their wiring looms). I will eventually replace this or add a heat sleeve to protect more from the heat…

I didn’t take any pictures of the knuckle job or other maintenance since it is heavily documented by others on the forum. I also flushed the coolant system at home as much as I could but it was in very poor shape with a lot of buildup. Once I put everything back together I took the 80 to a local radiator shop so they could pressure flush the coolant system in hopes of getting as much sediment out as possible. (Yes, this is foreshadowing of problems to come…)

After all this hard work I drove the 80 for a couple of months enjoying it and fixing little things here and there…

Changed the stripped seat gears…

Cleaned the contacts on my drivers window switch…

Dealt with clogged sunroof drains. I also added a thicker seal to a piece on the sunroof rail to stop water from coming into the headliner area.

I found the correct remote for my alarm system. I could not find anyone else with this FCC ID on their control box to figure out what remote to purchase. So I looked on other forums and made an educated guess at the correct remote, luckily I got it on the first try! If the FCC ID on your control box is BAB237000-128 then a remote with the FCC ID BAB237131-022 will work.

I replaced my broken antenna cable. Kinda a pain but can be done in about 20 minutes…

Replaced this exhaust mount…

I also replaced my front speakers with some Pioneer TS-G1645R and for the rears I used some Pioneer TS-G1045R. No pictures of this but they fit almost perfectly in the LX doors. I also installed a ScanGauge at the same time.

THE MOMENT YOU ALL HAVE BEEN WAITING FOR!!! After all this work and driving if about 2-3,000 miles the head gasket blew. You can read more about my head gasket story on this thread… No heat, overheating and coolant full??, my first post is #18. I thought about doing the head gasket job myself but honestly I didn’t have the time, space, or experience to do it. I decided to have Trollhole do it instead. They did an awesome job and documented everything. Marshall and Greg are very knowledgeable. We did have some small issues but they did everything in their power to make them right. I’ll detail those issues later.

I had the 80 towed on a flatbed to their shop about 1 hour from my house. These are engine bay shots of how they got it…

Camshafts coming out…

Head off…

Last edited: