- Thread starter

- #41

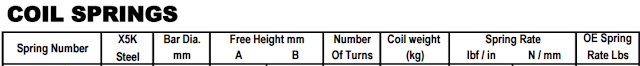

THAT CHART HAS THE WRONG INFORMATION.

I purposely did not use this chart because a few specs are wrong.

The wire or bar diameter on the 851, 850 & 850J are not all the same, they are .5mm different from each other.

The correct diameter are16mm, 16.5mm & 17mm.

That chart reads as all 3 springs at 17mm/.669" this is incorrect.

After looking directly from the current OME pdf it corrects all the confusion that I have had. Here is the correct onfo.

I called & wrote Emails to notify Cruiser Outfitters @cruiseroutfit of this but nothing was changed on thier end.

This is the chart that messed me up for years till I finally went to the OME pdf.

Also on the 861 & 862 they have them down as single rate coils when they are dual rate.861 is 170/250 & 862 is 170/260

See this thread to get the rest of the story. OME 851, 850 & 850J what is the difference?

I'm glad I have taken the time to finally get this info all in one place, now I can even come back to reference to this.

I will reference the other stuff when I get more time. Thank you all for your participation.

Last edited: