YotaJosh

SILVER Star

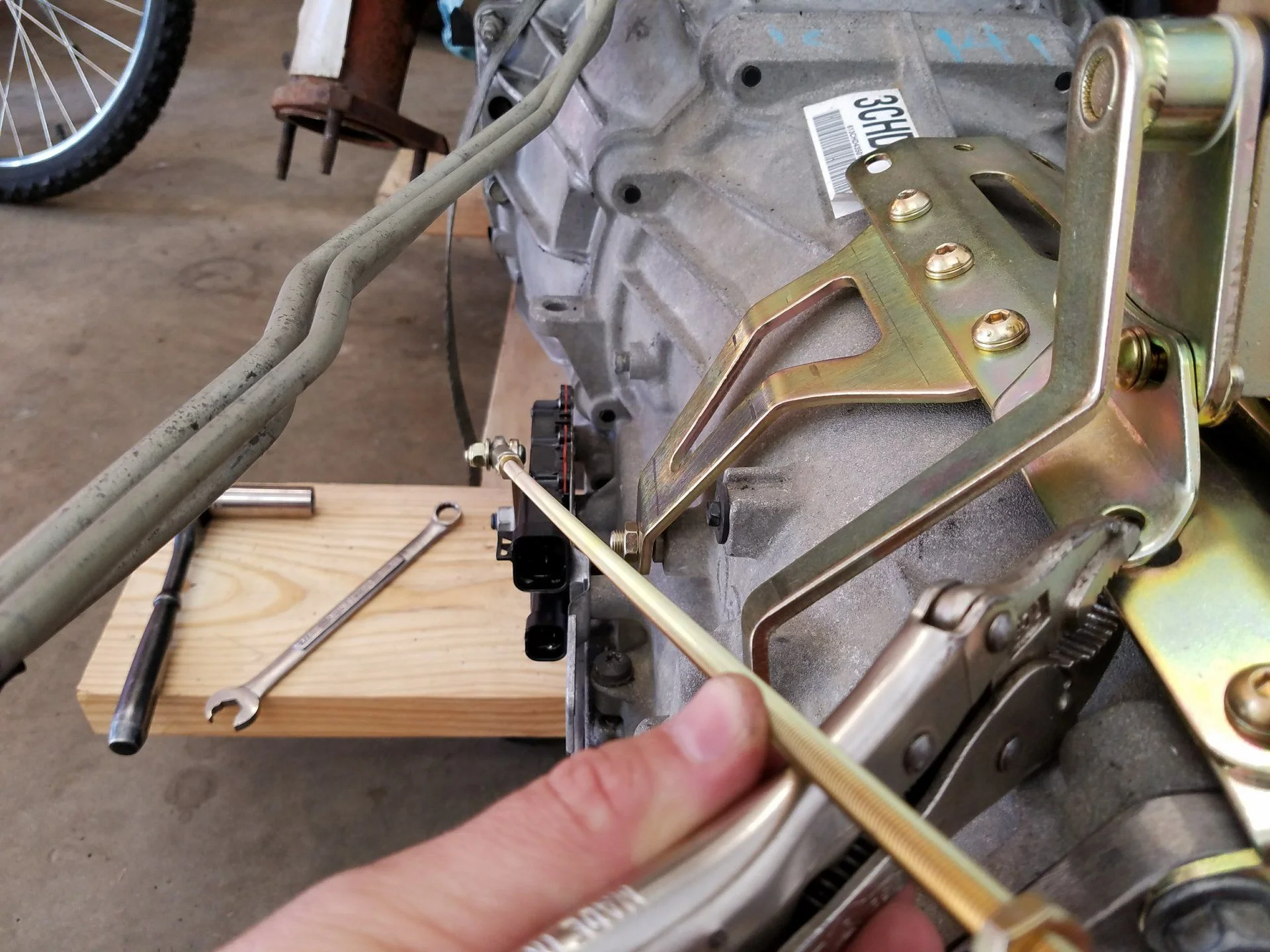

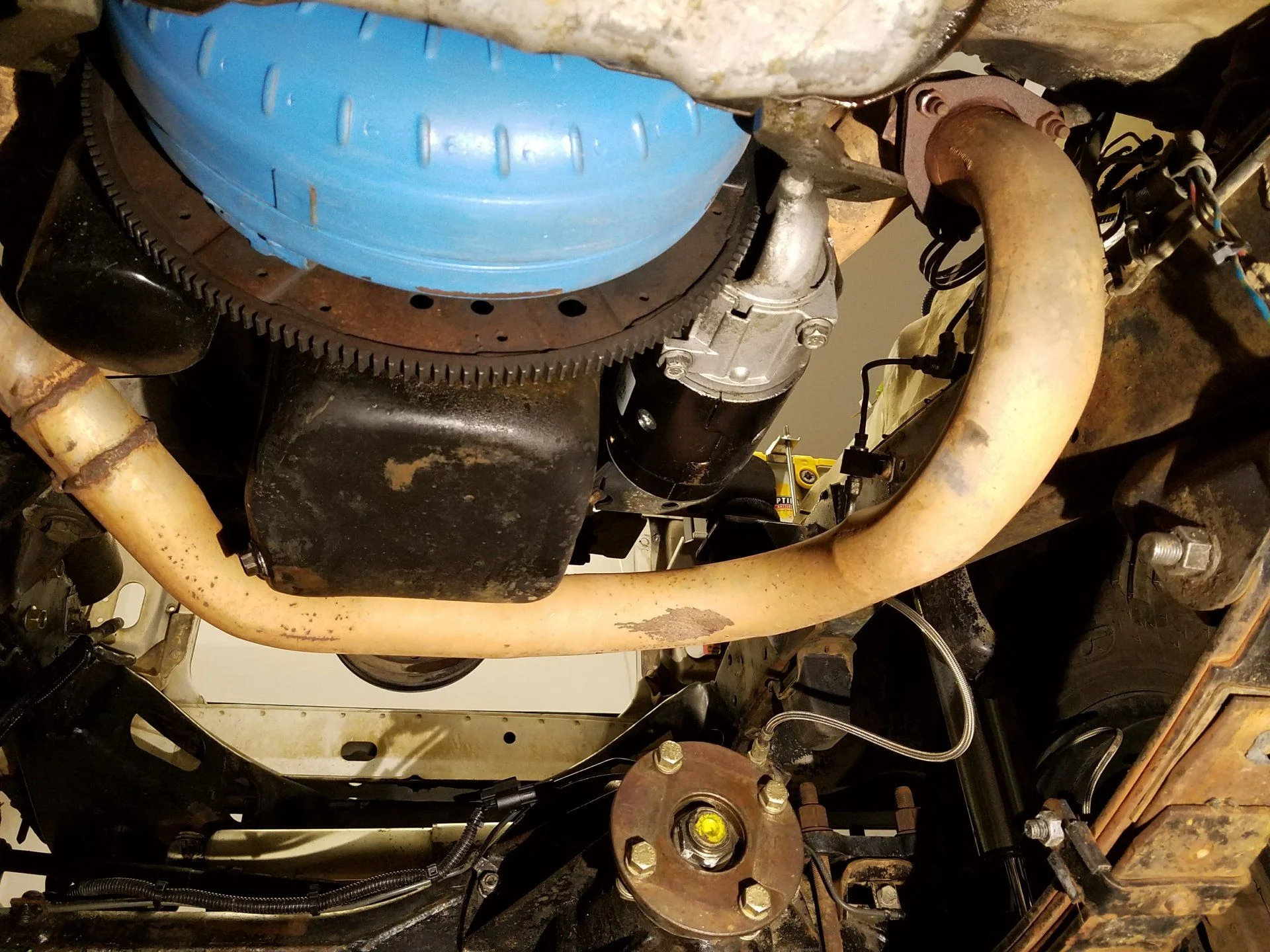

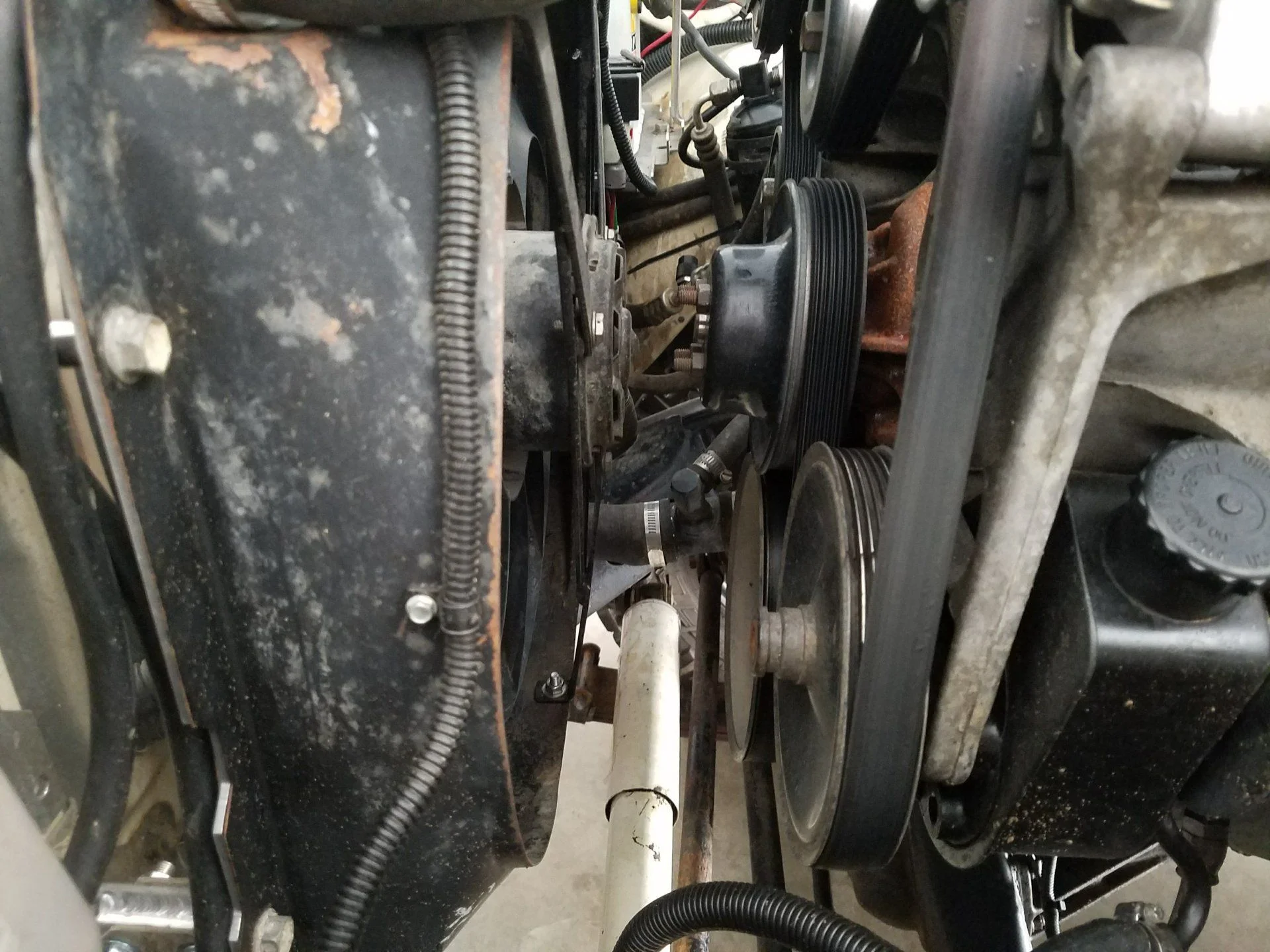

So I've owned my 1987 FJ60 for 5 years now. I bought it locally, and someone other than him had swapped out the 2F and 4 speed for a 5.7l 350 TBI injected motor, mated to a 700R4 transmission and adapted to the stock split case transfer case using the typical Advance Adapters hardware.

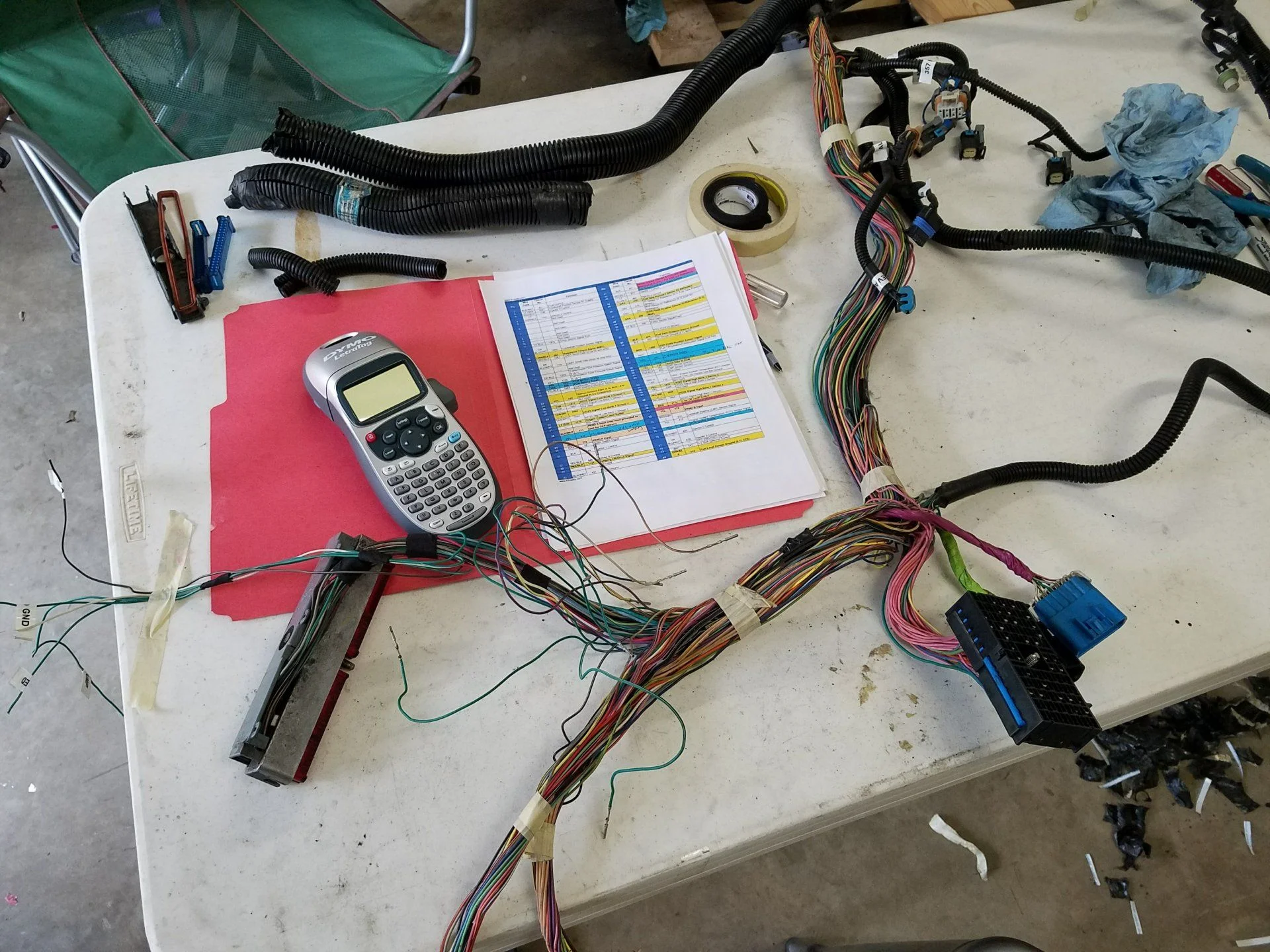

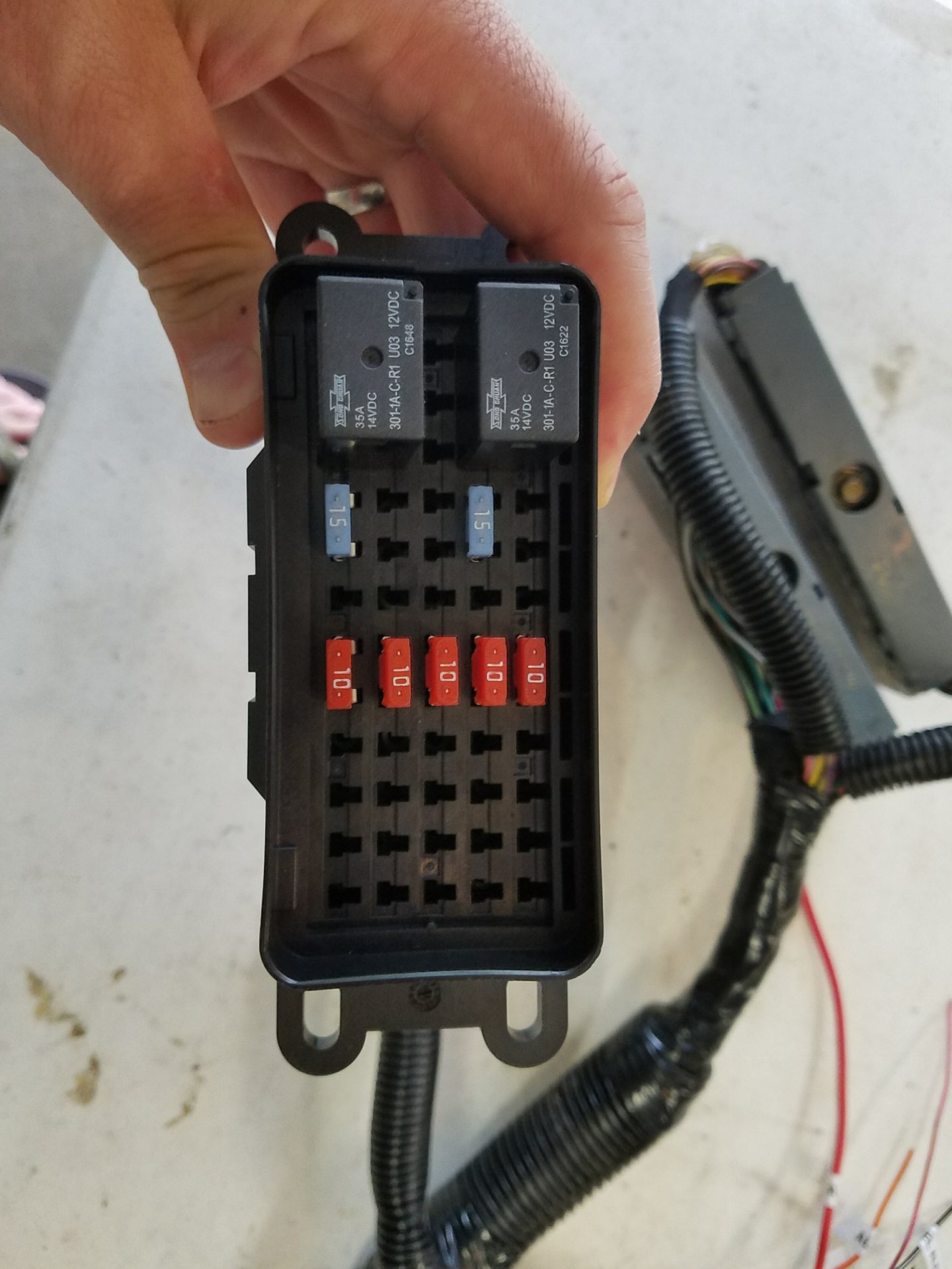

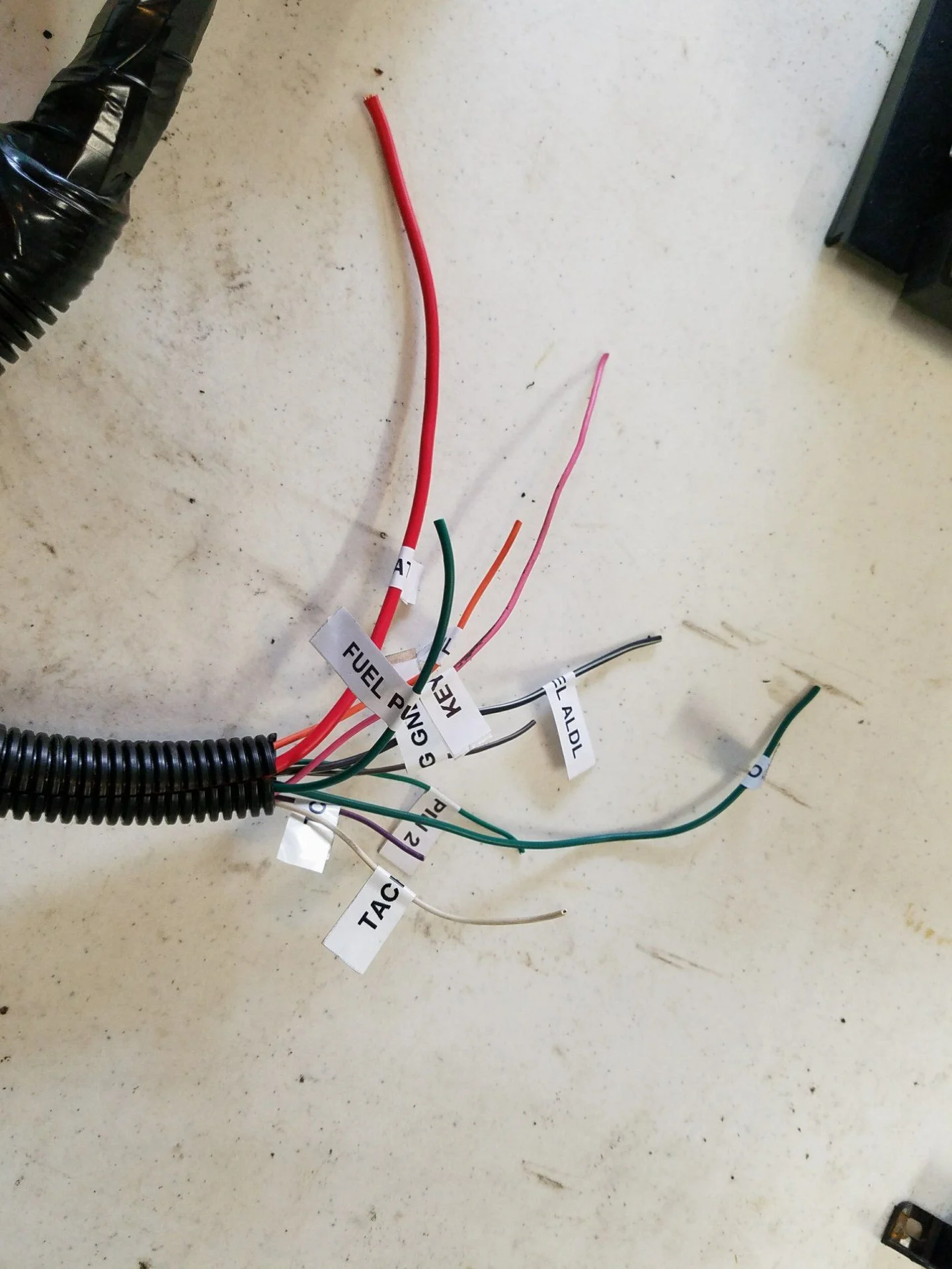

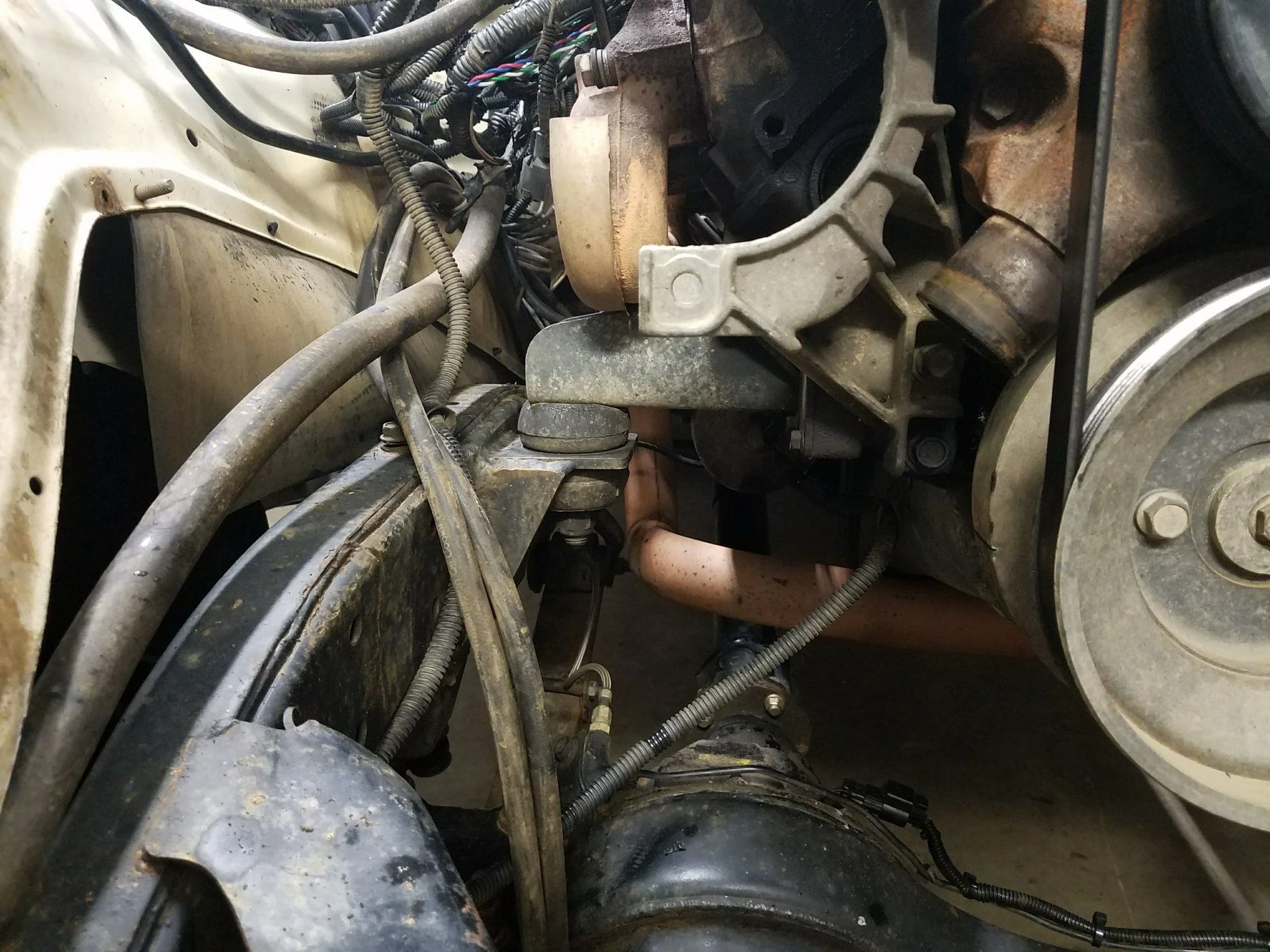

All in all, it was a great combo to start with. There were lots of little things with the swap I was never happy with. The engine sat too high, the wiring harness was not done correctly, or routed well on the engine. The exhaust was restrictive. And somebody got creative and used all the "power tricks" from the 90's to try and squeeze more power out of it. Like a fuel pump pushing 40 psi (TBI needs 12ish), a fuel regulator set all wrong, timing bumped up way to high, an Ebay ECM "chip" with terrible tuning, and a few other things. Once I changed one thing, the whole system pretty much failed and I had to take it all back to stock.

In the 5 years I've daily driven it (yep, it's my daily driver, and I have 3 kids!), I've been toying with an engine rebuild or swap. I priced out a rebuilt crate engine from Summit to just replace what I have, and it was around $1700, before I started doing the "while I'm in there" stuff. And I would probably not break 200HP out of it.

Being a Cruiser junkie, I watch craigslist like a hawk. I've been expanding my searches for mid 2000's Chevy trucks, Tahoe's, and Suburbans to snatch the running gear out of. One day a 2002 Tahoe that had been rolled popped up for $1200. I went to look at it (at a local junkyard) and someone beat me to it, but they had another one.

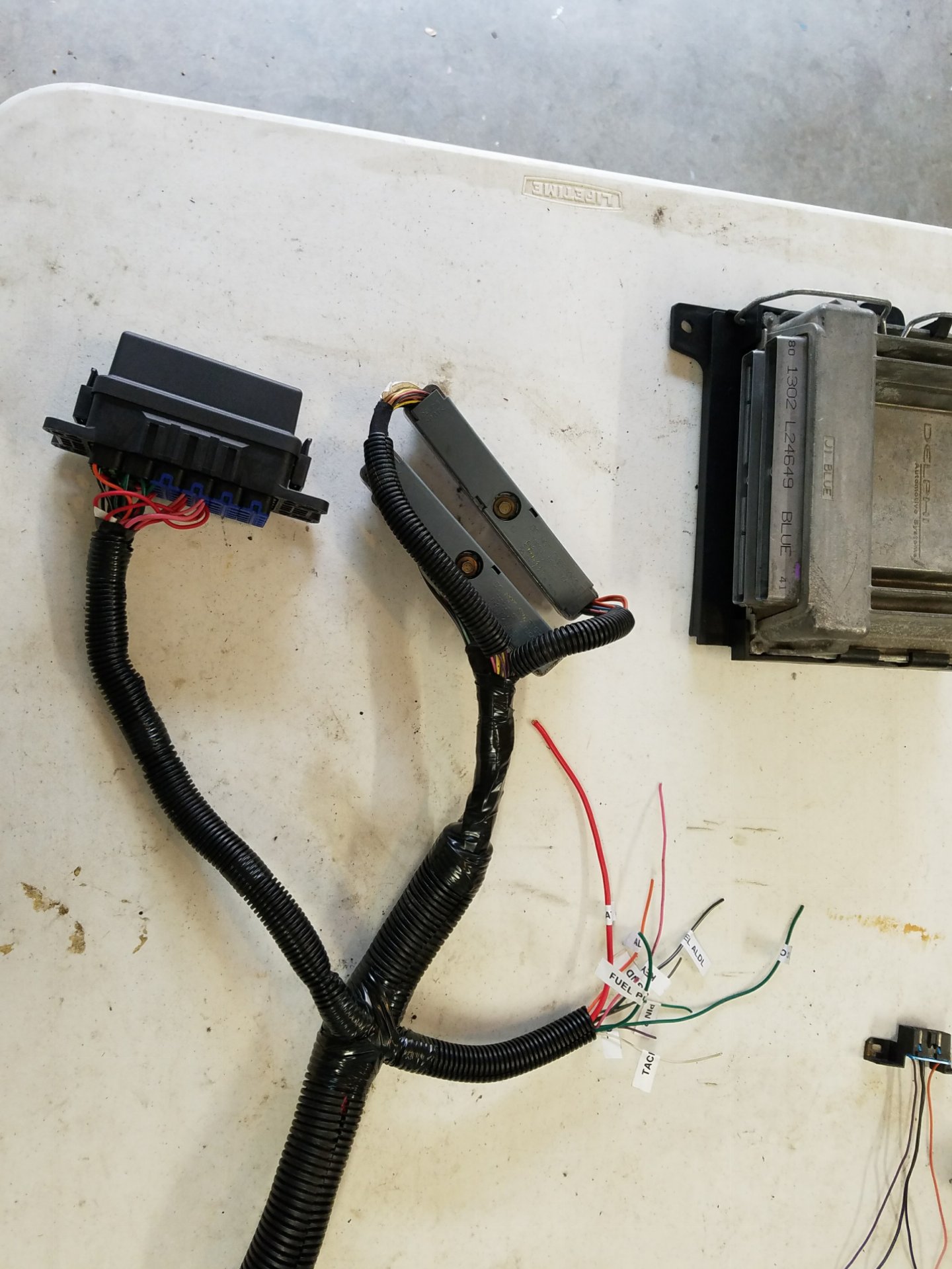

The one they pointed me at ran and drove. It had some front damage that they were hoping to repair and flip it, but money talks and parts started selling off of it. But the engine and trans were complete. I traded them a Toyota 3.0 V6 auto trans and tcase and got the engine, trans, ECM, and wiring for $1000.

The downside to the good price is the Tahoe no longer could be started as the steering column had been removed and other dash components. So I didn't hear it run, nor do I know the exact mileage. I was told 160,000 or so. And the truck did lot drive just fine. So I'm working on good faith here...

So out with the tired 1991 5.7l TBI and in with the 2002 5.3l L59!

Oh, and this my FJ60. My youngest daughter named it "Wilbur" (after the pig in Charlotte's Web) the day we bought it, but we rarely call it that.

Fresh from the junkyard. And just an hour before it was sitting in a Tahoe.

All in all, it was a great combo to start with. There were lots of little things with the swap I was never happy with. The engine sat too high, the wiring harness was not done correctly, or routed well on the engine. The exhaust was restrictive. And somebody got creative and used all the "power tricks" from the 90's to try and squeeze more power out of it. Like a fuel pump pushing 40 psi (TBI needs 12ish), a fuel regulator set all wrong, timing bumped up way to high, an Ebay ECM "chip" with terrible tuning, and a few other things. Once I changed one thing, the whole system pretty much failed and I had to take it all back to stock.

In the 5 years I've daily driven it (yep, it's my daily driver, and I have 3 kids!), I've been toying with an engine rebuild or swap. I priced out a rebuilt crate engine from Summit to just replace what I have, and it was around $1700, before I started doing the "while I'm in there" stuff. And I would probably not break 200HP out of it.

Being a Cruiser junkie, I watch craigslist like a hawk. I've been expanding my searches for mid 2000's Chevy trucks, Tahoe's, and Suburbans to snatch the running gear out of. One day a 2002 Tahoe that had been rolled popped up for $1200. I went to look at it (at a local junkyard) and someone beat me to it, but they had another one.

The one they pointed me at ran and drove. It had some front damage that they were hoping to repair and flip it, but money talks and parts started selling off of it. But the engine and trans were complete. I traded them a Toyota 3.0 V6 auto trans and tcase and got the engine, trans, ECM, and wiring for $1000.

The downside to the good price is the Tahoe no longer could be started as the steering column had been removed and other dash components. So I didn't hear it run, nor do I know the exact mileage. I was told 160,000 or so. And the truck did lot drive just fine. So I'm working on good faith here...

So out with the tired 1991 5.7l TBI and in with the 2002 5.3l L59!

Oh, and this my FJ60. My youngest daughter named it "Wilbur" (after the pig in Charlotte's Web) the day we bought it, but we rarely call it that.

Fresh from the junkyard. And just an hour before it was sitting in a Tahoe.