Hey Peeps,

Well I was just finishing refilling my AC (easy as pie), when I noticed on my second start this funny metal noise... So I shut the engine off, it was the starter, it kept cranking!!!

So I quickly disconnected BOTH batteries to stop it from running!!!

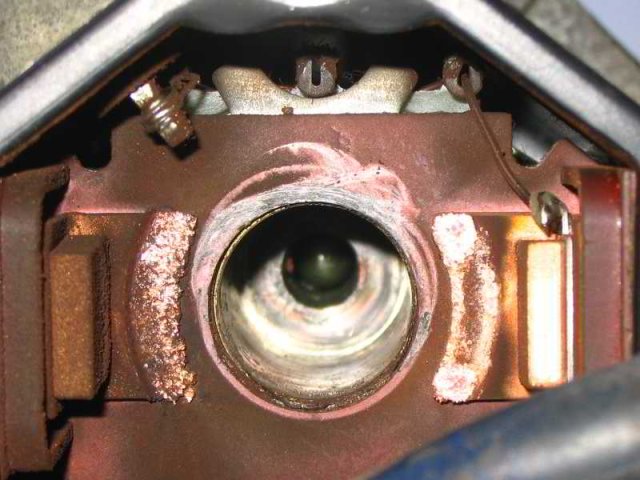

My understanding is, it would seem the starter gear is stuck to the flywheel and won't come off and the magnetic switch contacts are welded together...

When I connect the left hand side battery, the starter immediately cranks... What gives? I thought this starter needed 24 volts to turn over?!

I've never had that kind of problem before. How much work is it to fix? Now that I think of it, I've had the same kind of noise happen twice in the past year, but it didn't last very long and would stop after a few seconds so I never pursued the matter...

HELP

Well I was just finishing refilling my AC (easy as pie), when I noticed on my second start this funny metal noise... So I shut the engine off, it was the starter, it kept cranking!!!

So I quickly disconnected BOTH batteries to stop it from running!!!

My understanding is, it would seem the starter gear is stuck to the flywheel and won't come off and the magnetic switch contacts are welded together...

When I connect the left hand side battery, the starter immediately cranks... What gives? I thought this starter needed 24 volts to turn over?!

I've never had that kind of problem before. How much work is it to fix? Now that I think of it, I've had the same kind of noise happen twice in the past year, but it didn't last very long and would stop after a few seconds so I never pursued the matter...

HELP

I definitely learned something neat today

I definitely learned something neat today