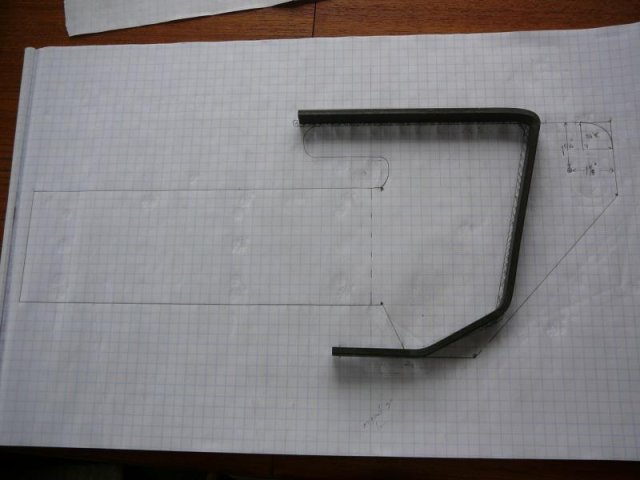

I wanted to build my own rear bumper. I have a 4+ on the front, and it's fantastic! Really well made and just enough without being too heavy. I got it as I was in a hurry to go north for a moose hunt and we were going into new territory and I needed a winch for the 'just in case' that might happen. North being 300 kms north of Ft St James, BC.

can't wait to c how this turn out i want the same for my truck

can't wait to c how this turn out i want the same for my truck