- Thread starter

- #61

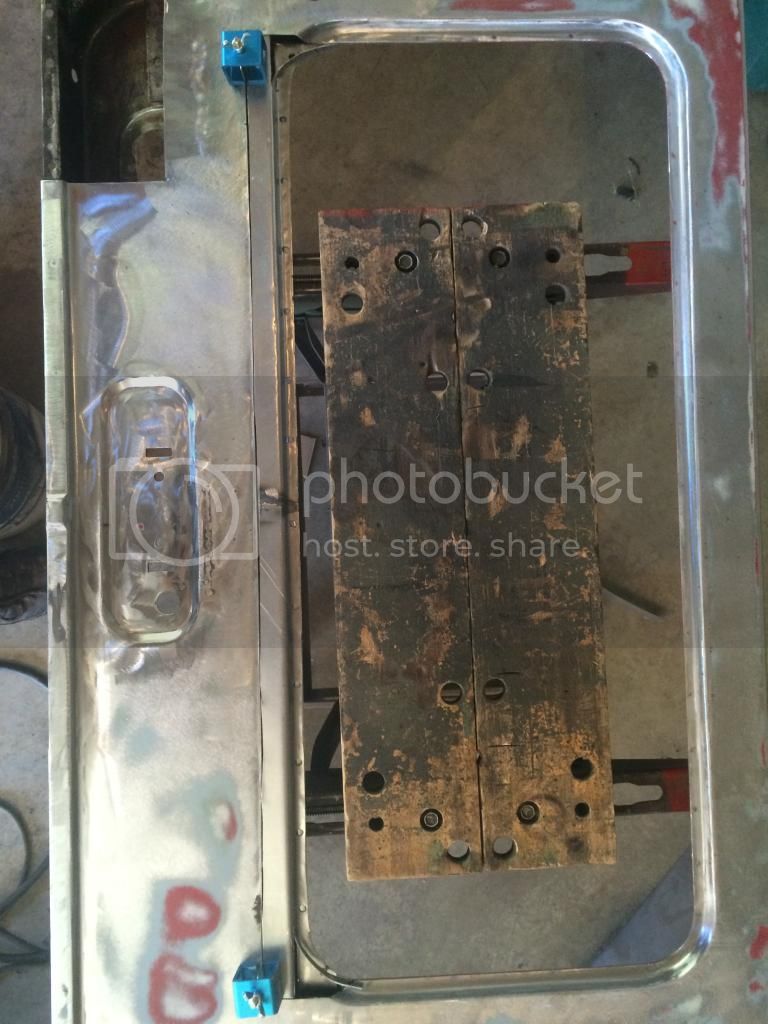

More rear hatch sheet metal work. I can now see how useful a shop press would be after faking my way through this particular repair with C clamps and an elcheapo 30” sheet metal break. The hatch is ready for a little body filler then paint.