Figured I would add some tech to the site I take alot from. Everything is a cut/paste from the orignal thread on PBB

http://www.pirate4x4.com/forum/showthread.php?t=761670

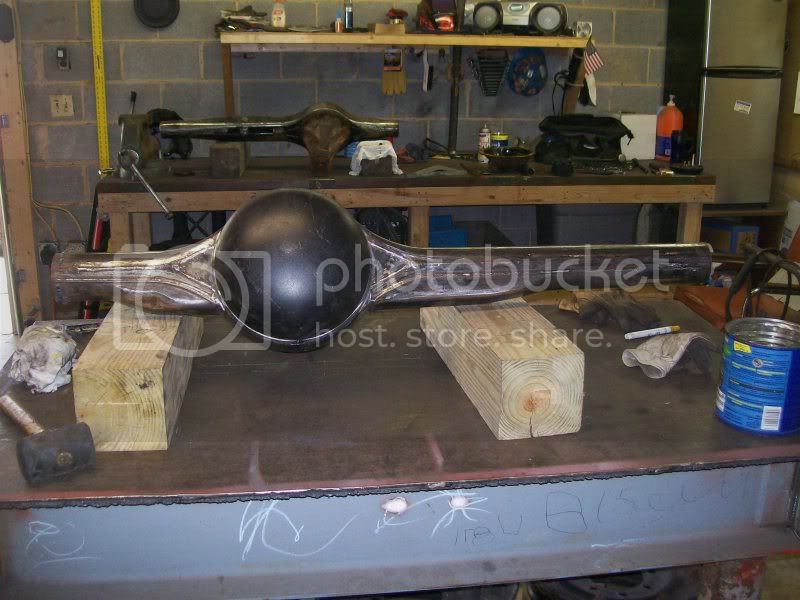

Somthing ive been working on. FJ62 rear flipped/turned, FJ80 outers. Im setting it up to use the stock 80 inners also so no custom inners are needed. I have the knuckles at a freind of a freinds cnc shop being drawn up on autocad this week for the high steer arms and ill drop off the balls (inners C's) today with my buddy so he can turn down the o.d. of the ball "slug" to fit the housing end. Pretty straight forward.

Slees uzj100 using the same setup, bling like though.

Ill be using the same type high steer setup.

When I got the housing. Ends were cut already. Beside a stock 80 front shaved/stripped down. Lots of rust to deal with on the housing.

Comparison pics of the LP 8" I was going to run and the 9.5"

Note the "tabs" on the 9.5" bearing caps, these contact the housing flange for support.

Started by cutting the knuckles off the 80 and cleaning the 62 up.

Here's how the 9.5 bearing caps are supported by the housing, almost like a 8.4 girdle. Also had to flip the diff back to low pinion, and notch the flange accordingly. This rear had a removable cover so that helped with it,otherwise the cover would have to be cut and turned.

Welded the cover on as I plan to shave/plate this one as well as have a a steering ram bridge/cover so it dosent need to be removeable. Also had to fill the stock fill hole and added a large one I had laying around.

http://www.pirate4x4.com/forum/showthread.php?t=761670

Somthing ive been working on. FJ62 rear flipped/turned, FJ80 outers. Im setting it up to use the stock 80 inners also so no custom inners are needed. I have the knuckles at a freind of a freinds cnc shop being drawn up on autocad this week for the high steer arms and ill drop off the balls (inners C's) today with my buddy so he can turn down the o.d. of the ball "slug" to fit the housing end. Pretty straight forward.

Slees uzj100 using the same setup, bling like though.

Ill be using the same type high steer setup.

When I got the housing. Ends were cut already. Beside a stock 80 front shaved/stripped down. Lots of rust to deal with on the housing.

Comparison pics of the LP 8" I was going to run and the 9.5"

Note the "tabs" on the 9.5" bearing caps, these contact the housing flange for support.

Started by cutting the knuckles off the 80 and cleaning the 62 up.

Here's how the 9.5 bearing caps are supported by the housing, almost like a 8.4 girdle. Also had to flip the diff back to low pinion, and notch the flange accordingly. This rear had a removable cover so that helped with it,otherwise the cover would have to be cut and turned.

Welded the cover on as I plan to shave/plate this one as well as have a a steering ram bridge/cover so it dosent need to be removeable. Also had to fill the stock fill hole and added a large one I had laying around.